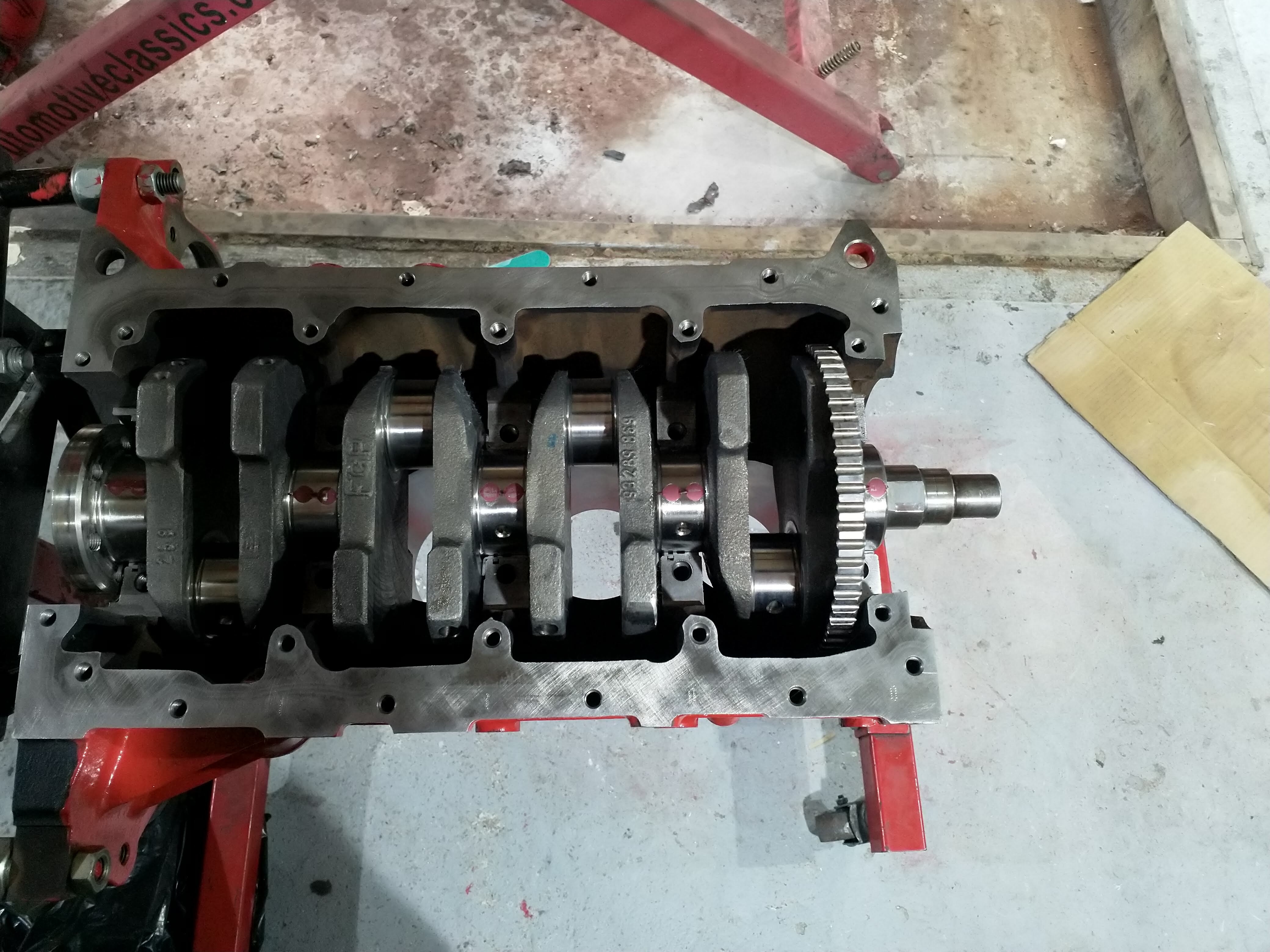

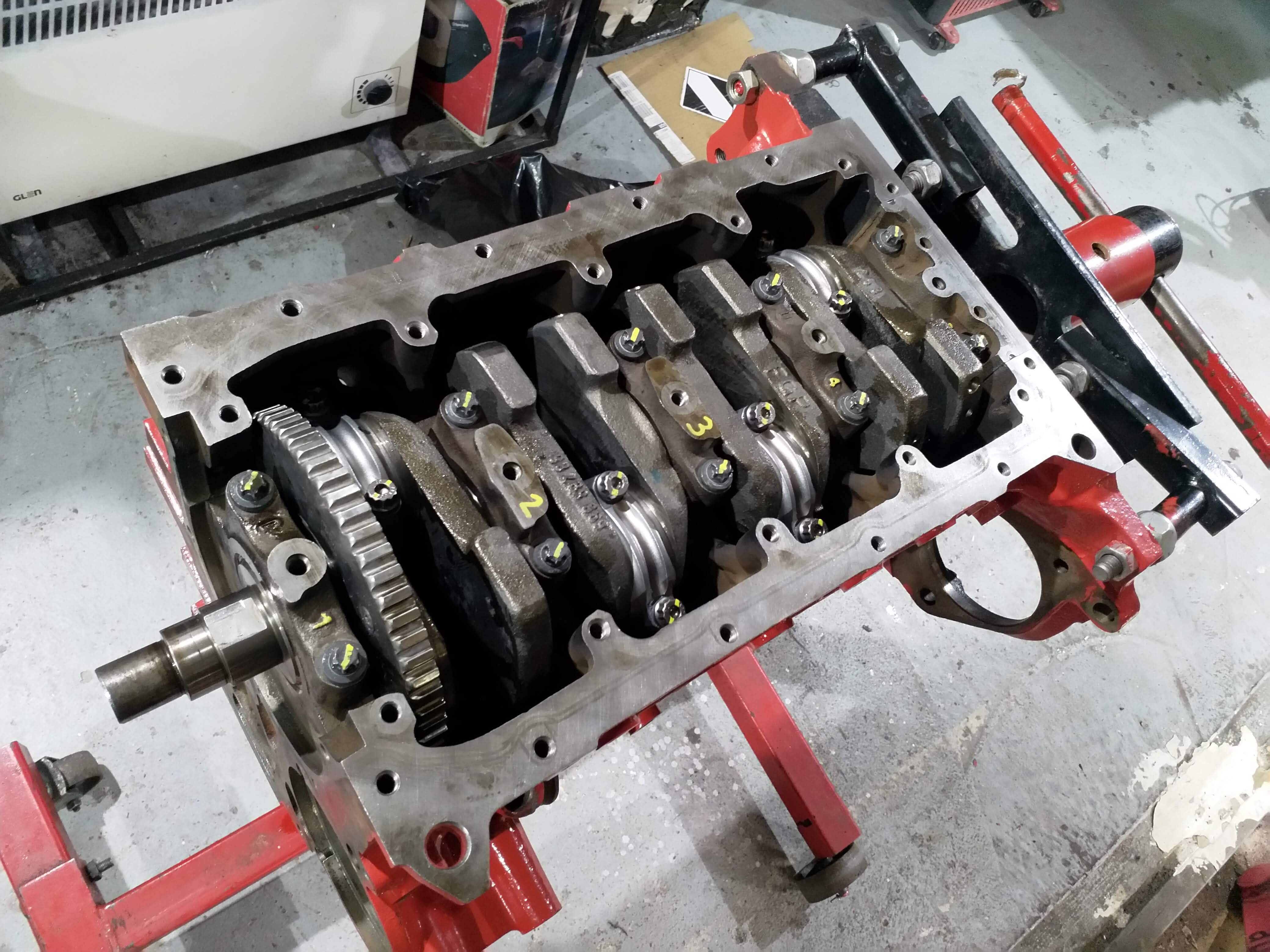

Next, i got the pistons on the rods, and fitted everything to Mahle and Arrow spec

All gudion pins facing upwards ( if you have them sideways, the up down force can cause the snap ring to squash and loose tension and fall out)

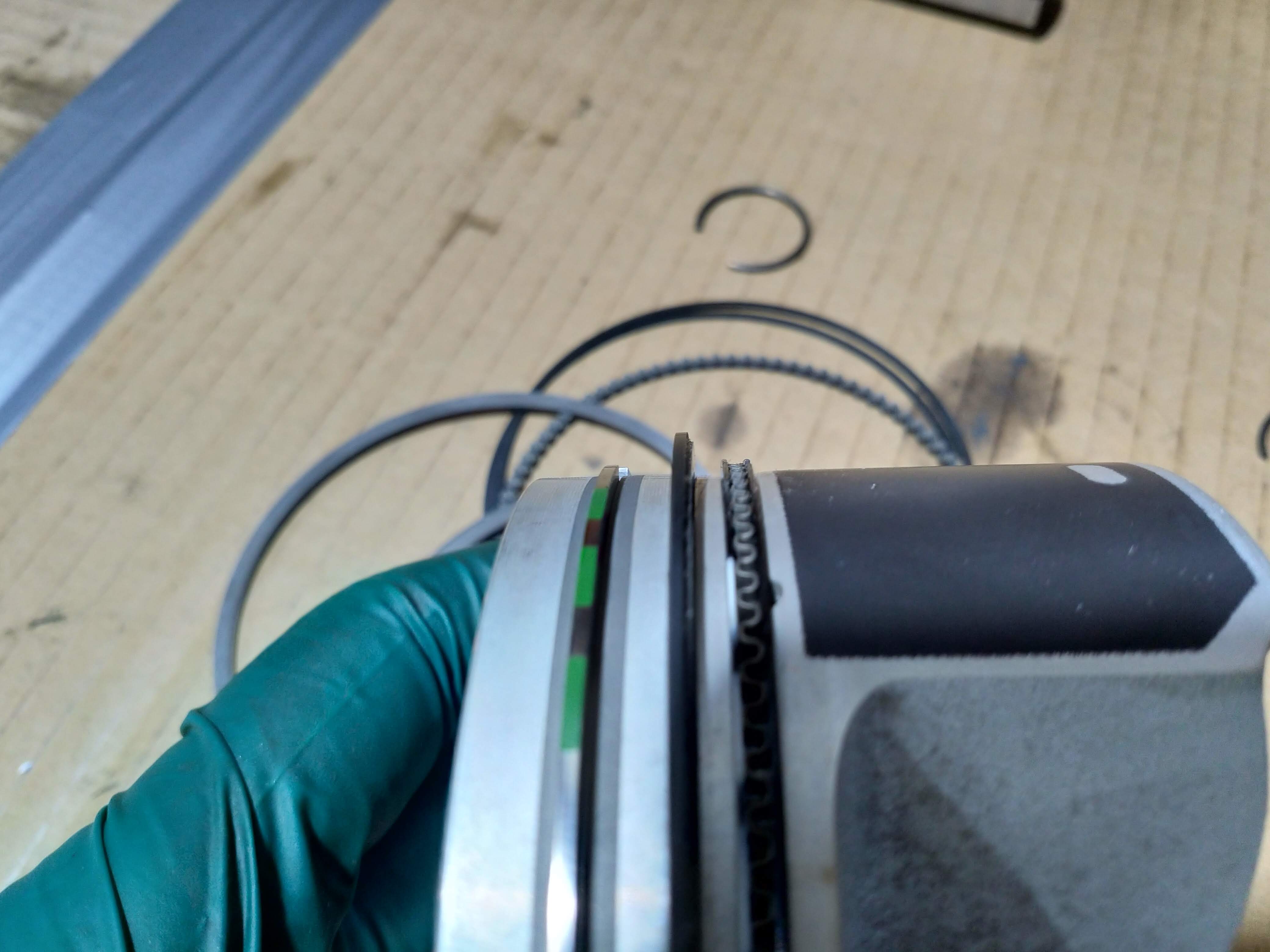

all rings fit 120 degrees apart with oil scrap gap 180 from scraper ring gaps

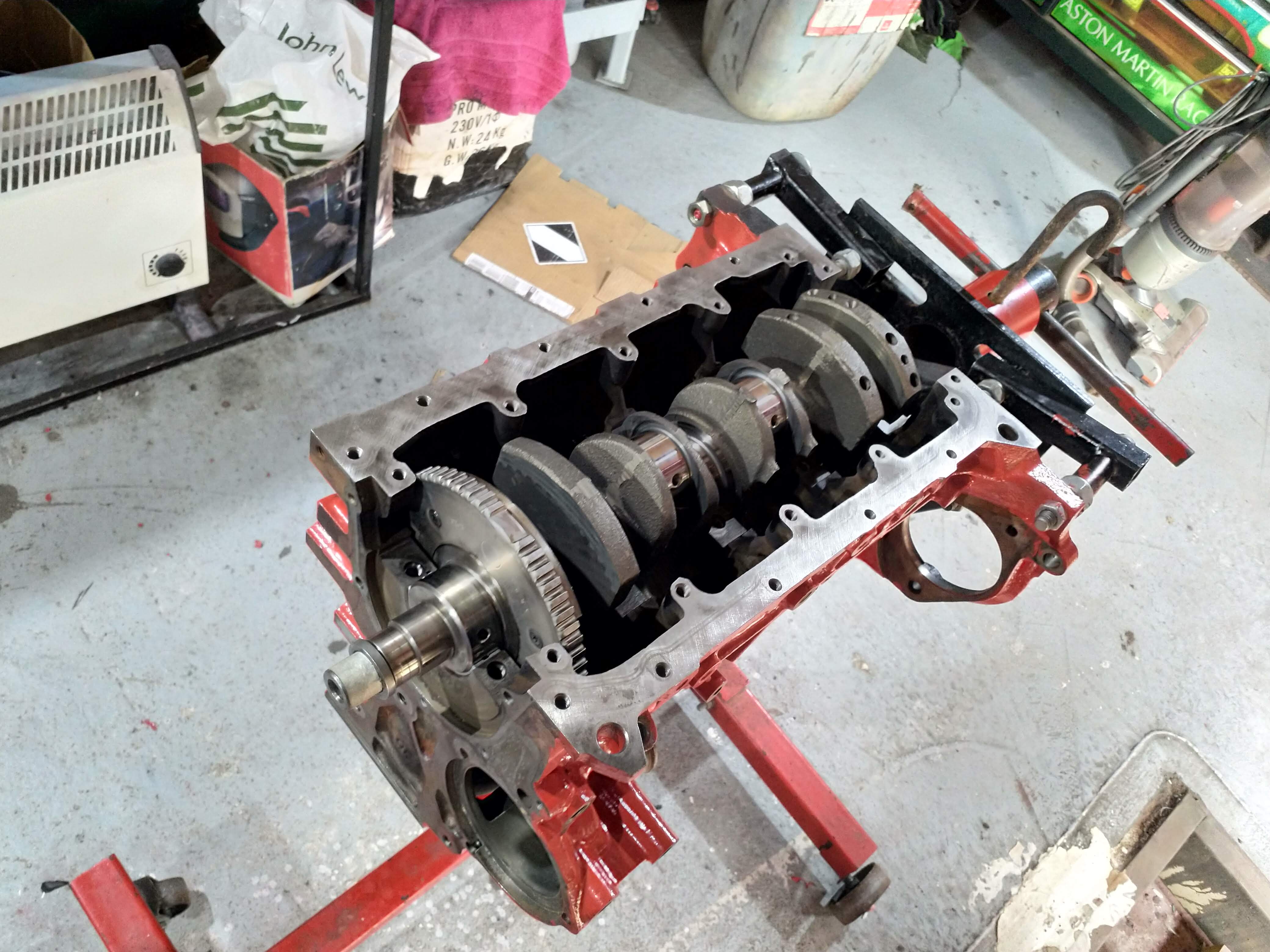

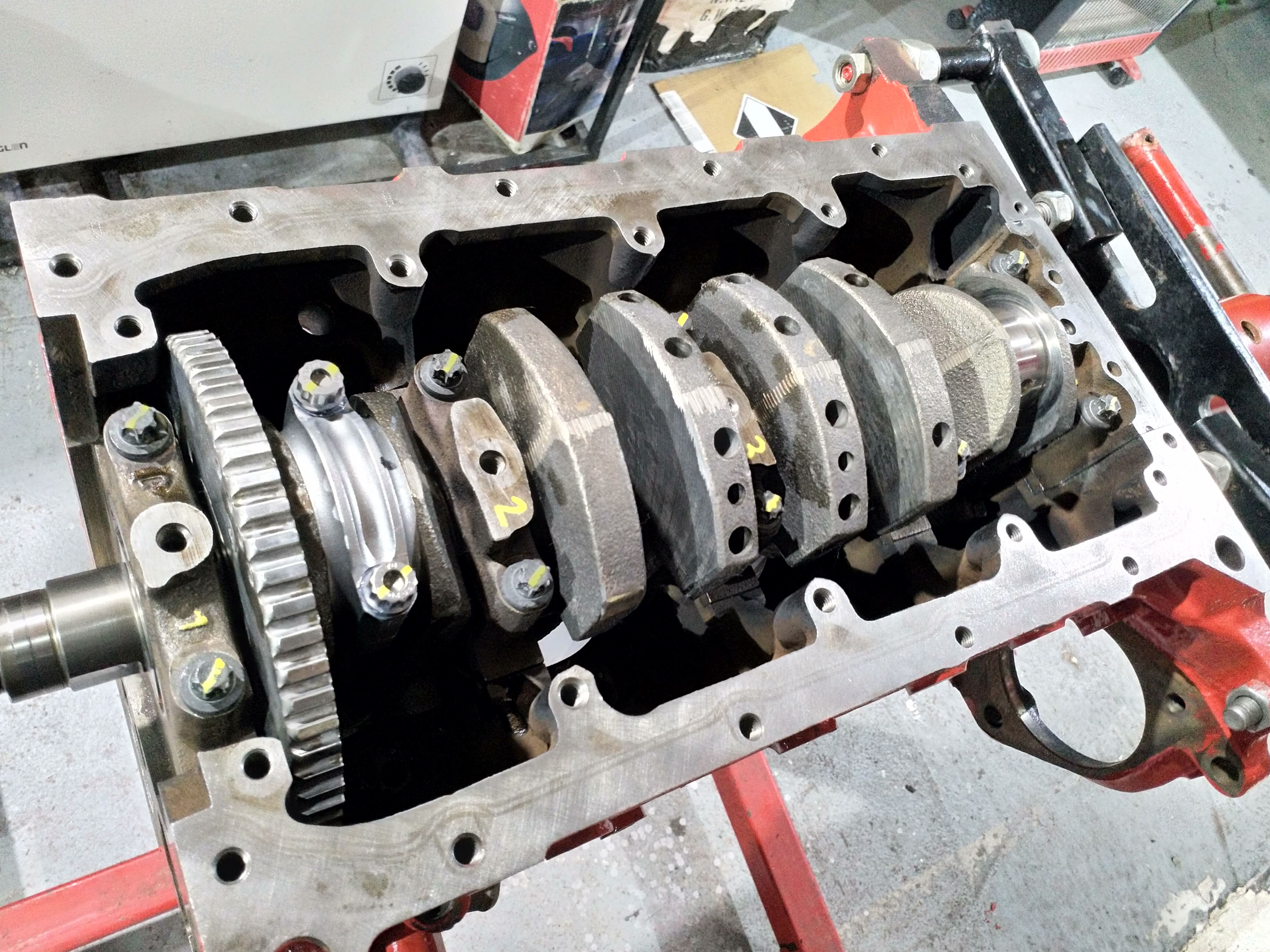

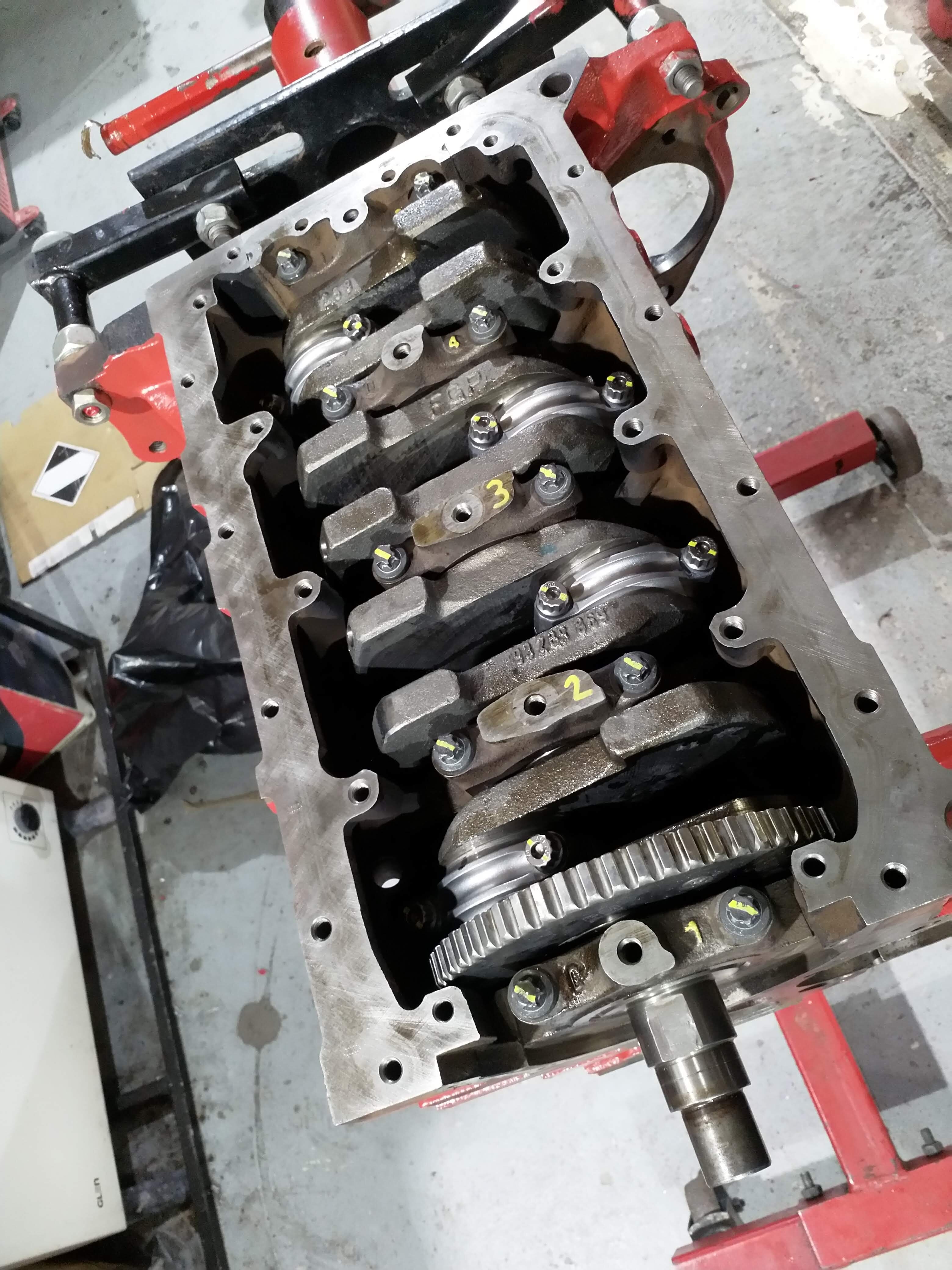

conrods fitted if the rod makes contact with the crank (which it never should!!!) the bearing 'stop notch' is against the cap, therefore it cannot physically spin a bearing.

All pistons and rods chucked in the bores using a ring compressor, all went in very nicely actually!

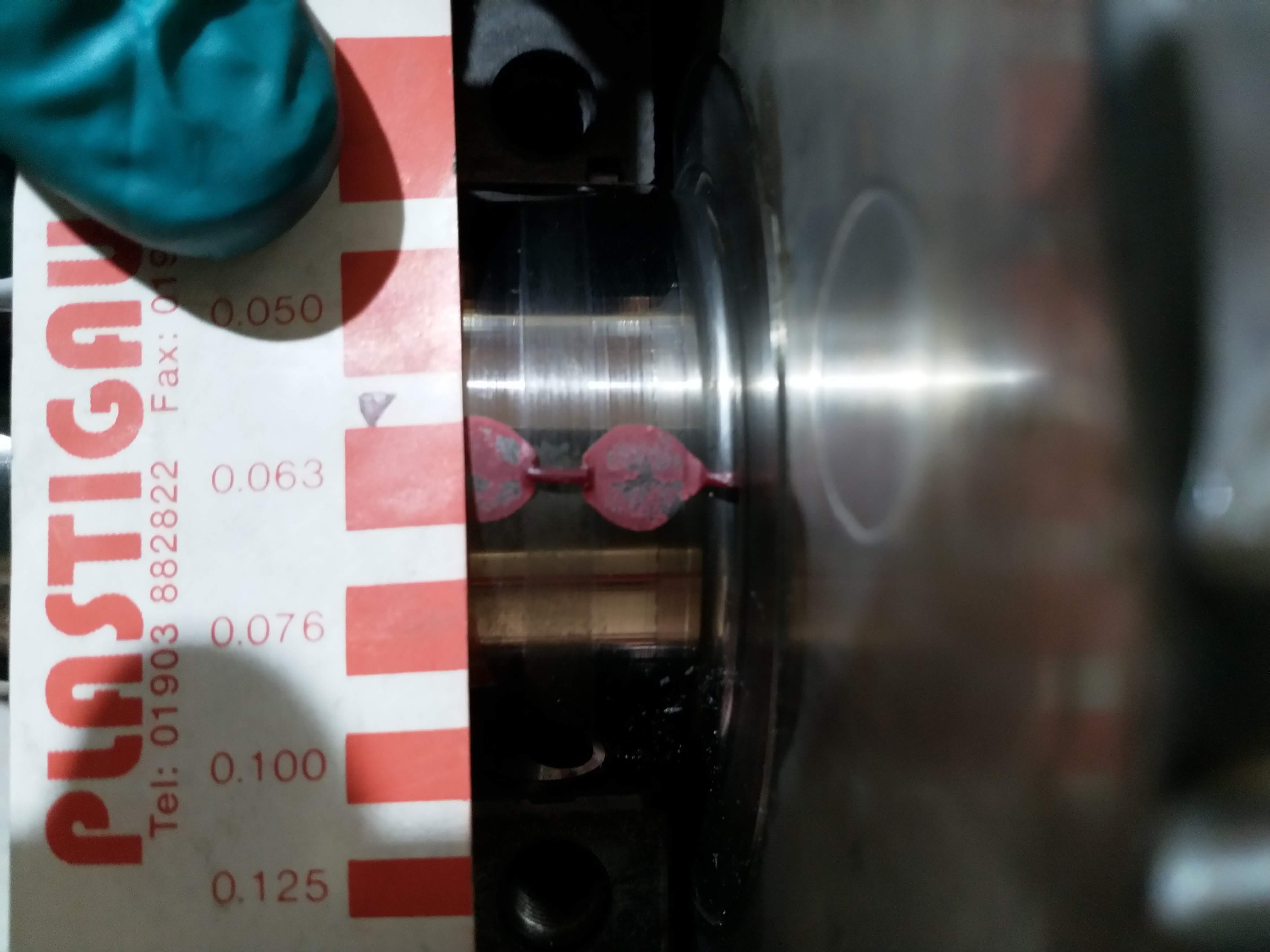

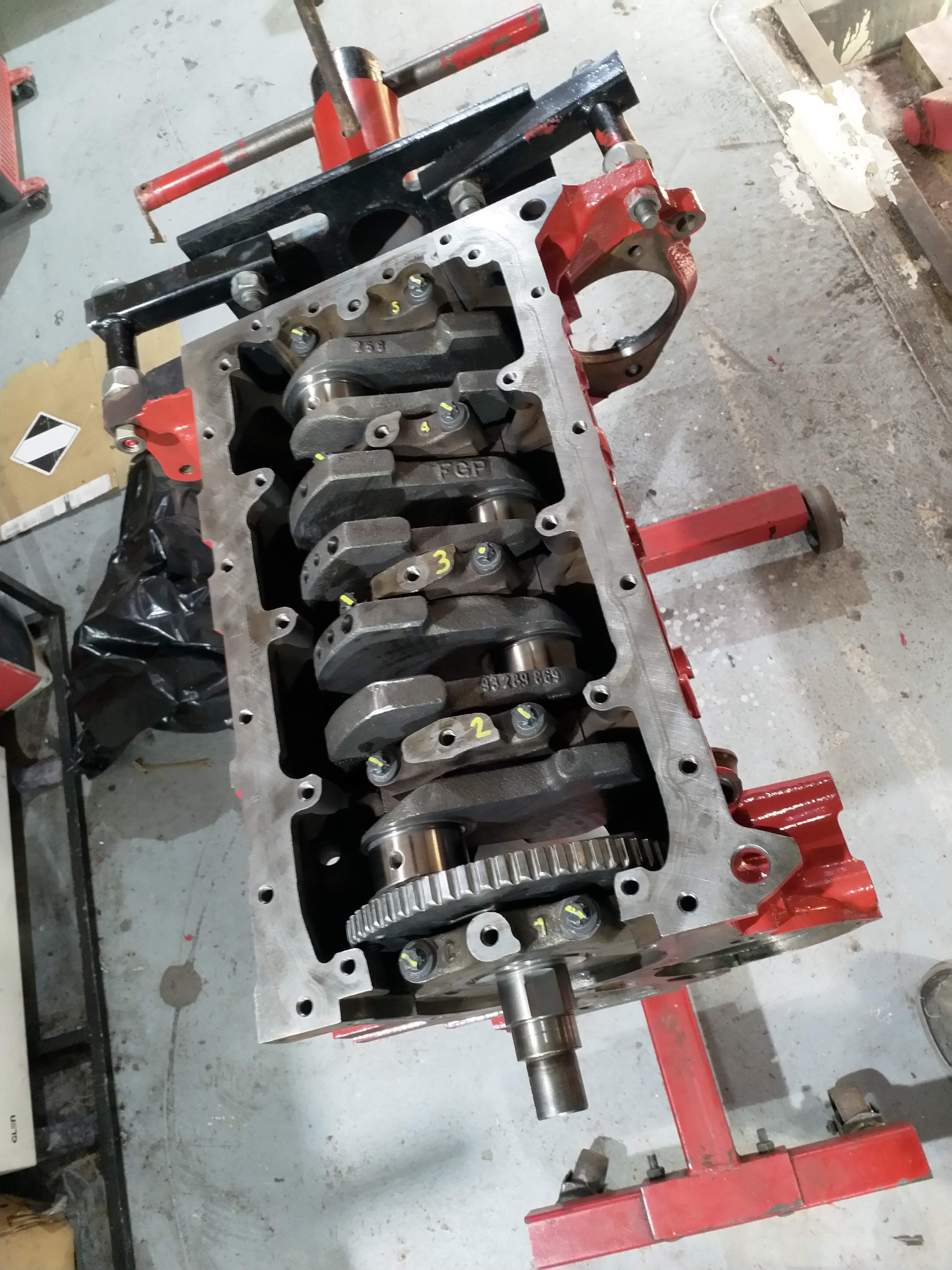

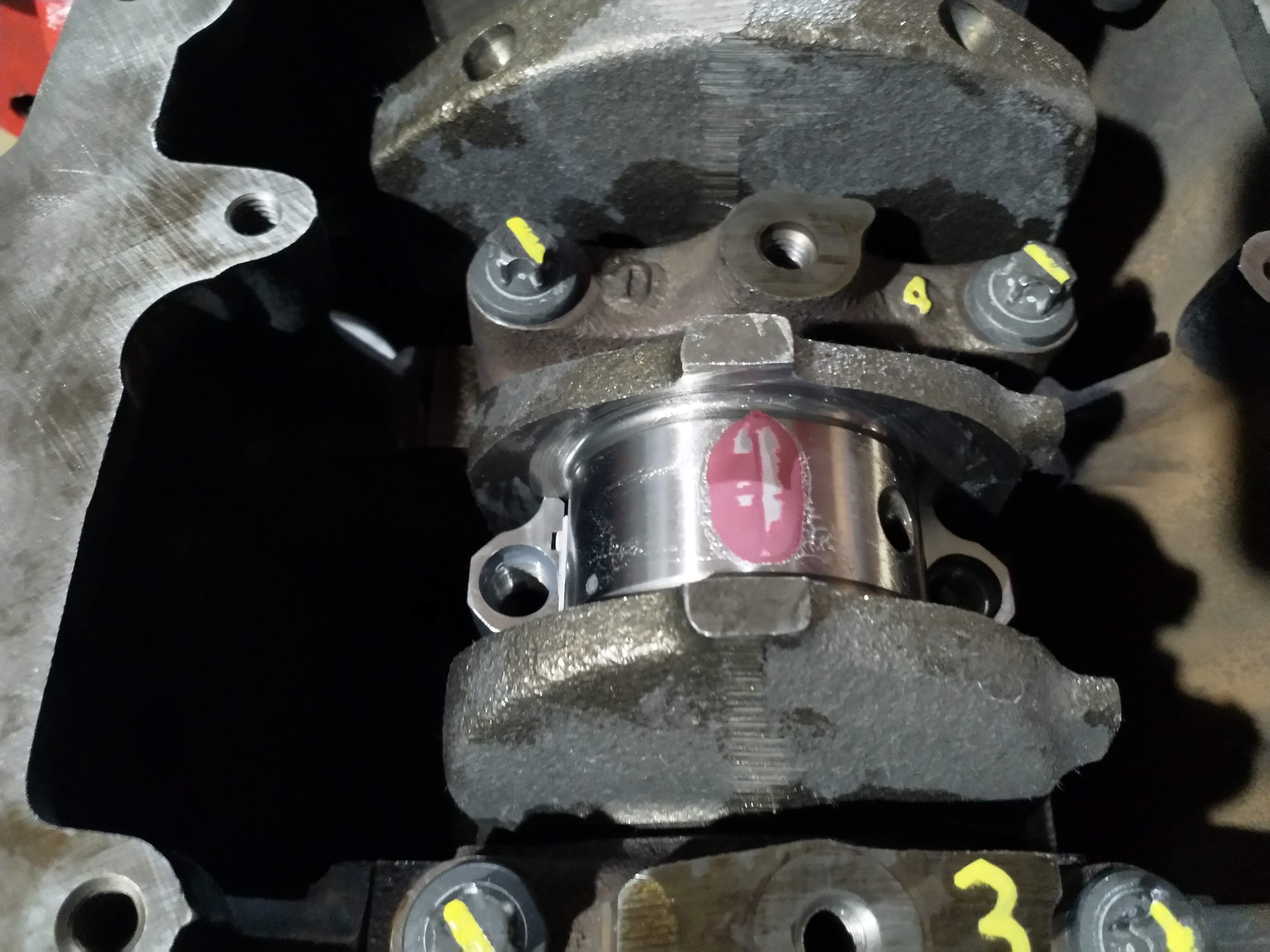

So next I plastigauged the Bigend. I know this seems backward to do it when everything is installed, But if you have measured everything as I have, I basically 'know' (

) this is going to be fine! Also its also easier to keep everything stationary like this and not 'smudge' the plastigauge.

Everything checks out spot on. Checked all 4, all good so cleaned up, smear of thick oil and rod caps on and torqued down. sexy

Lovely,

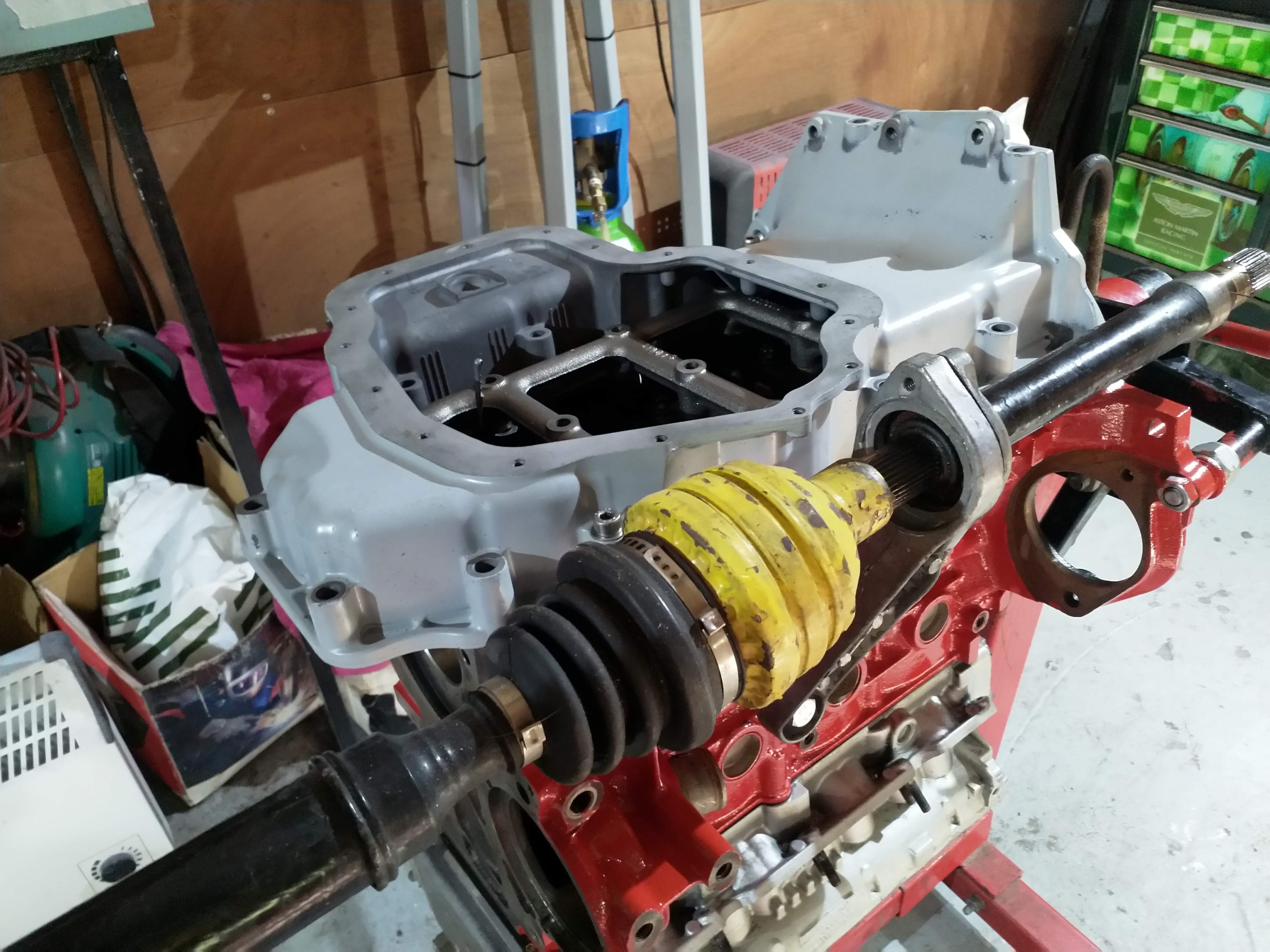

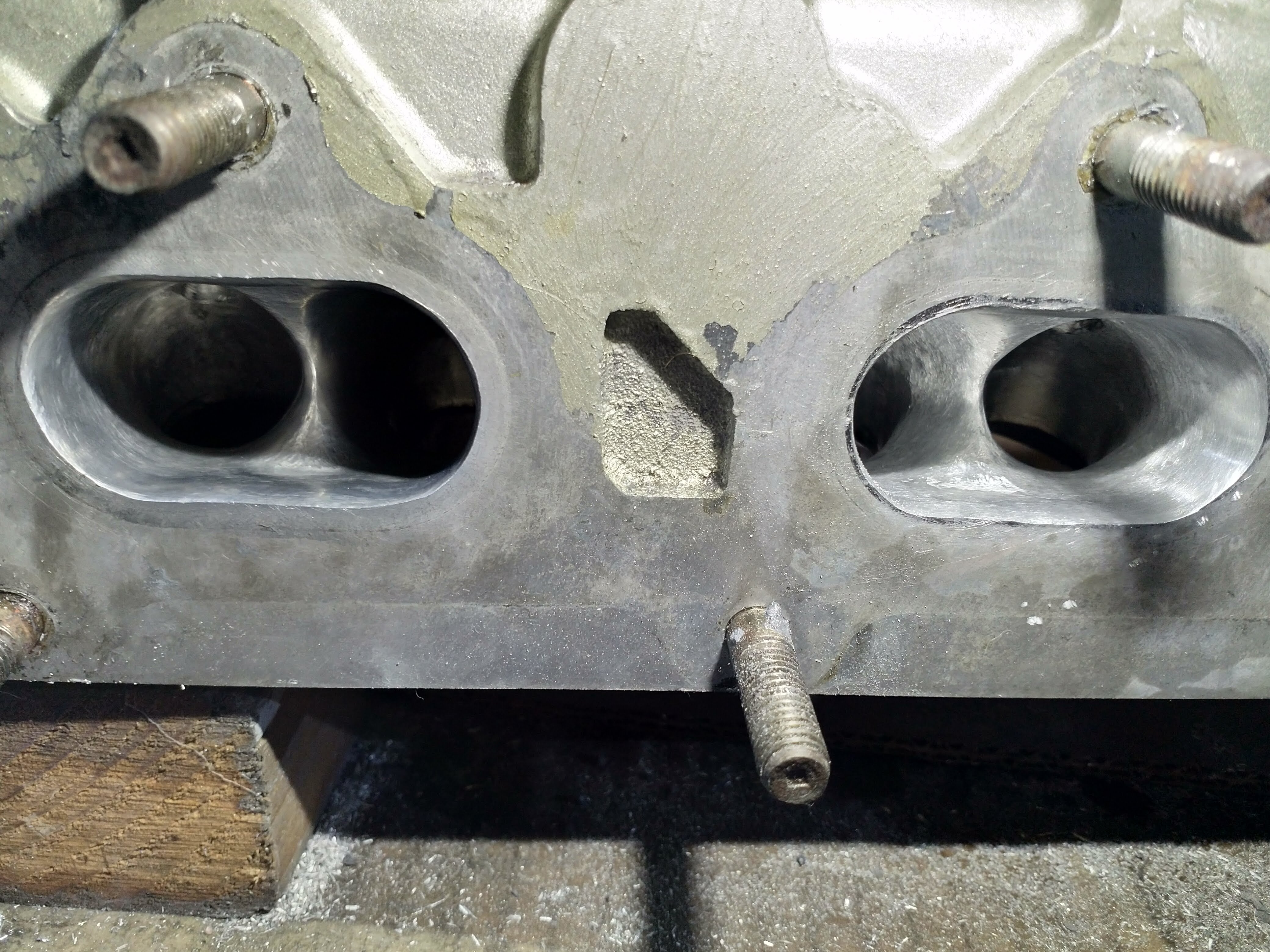

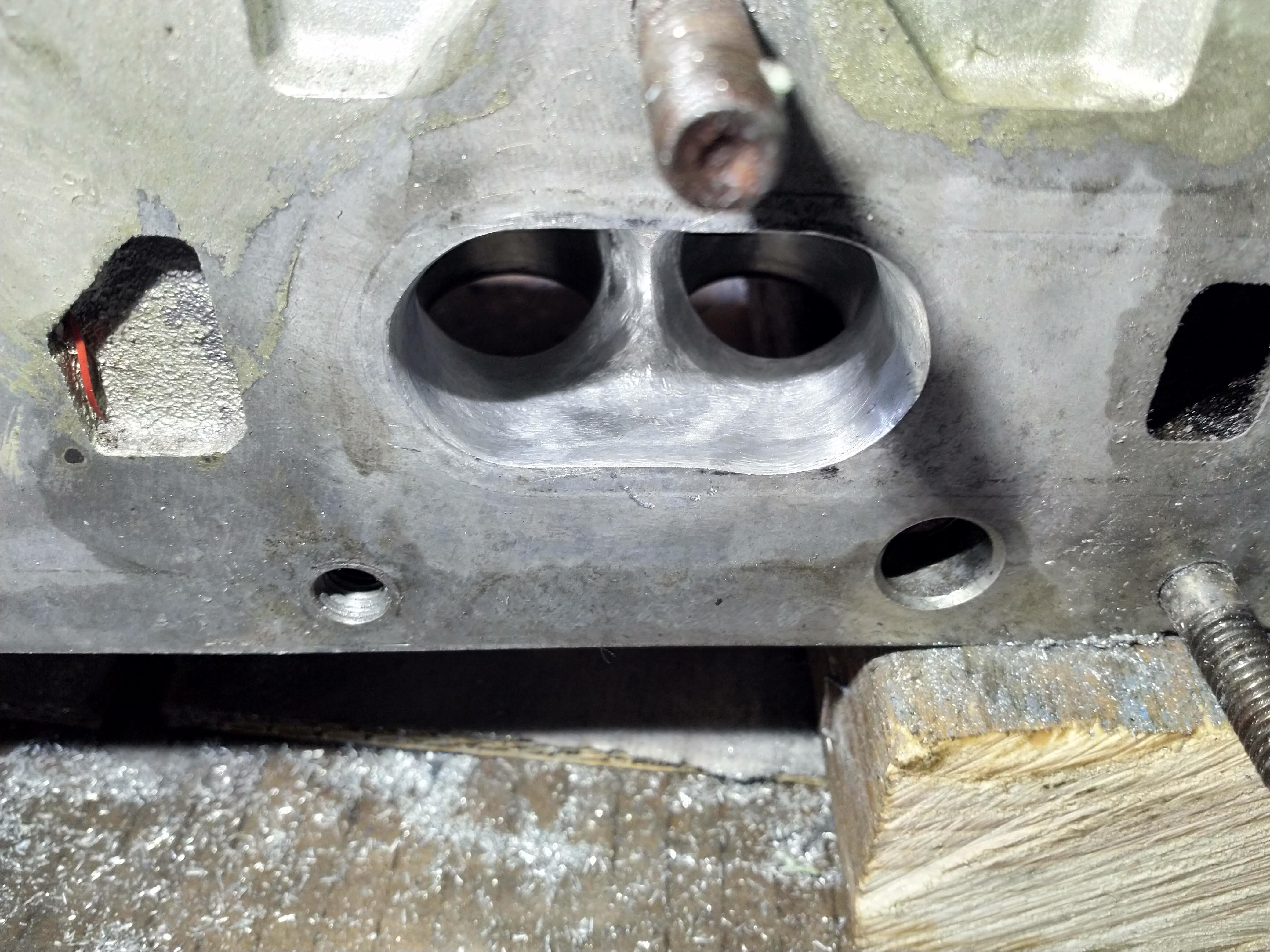

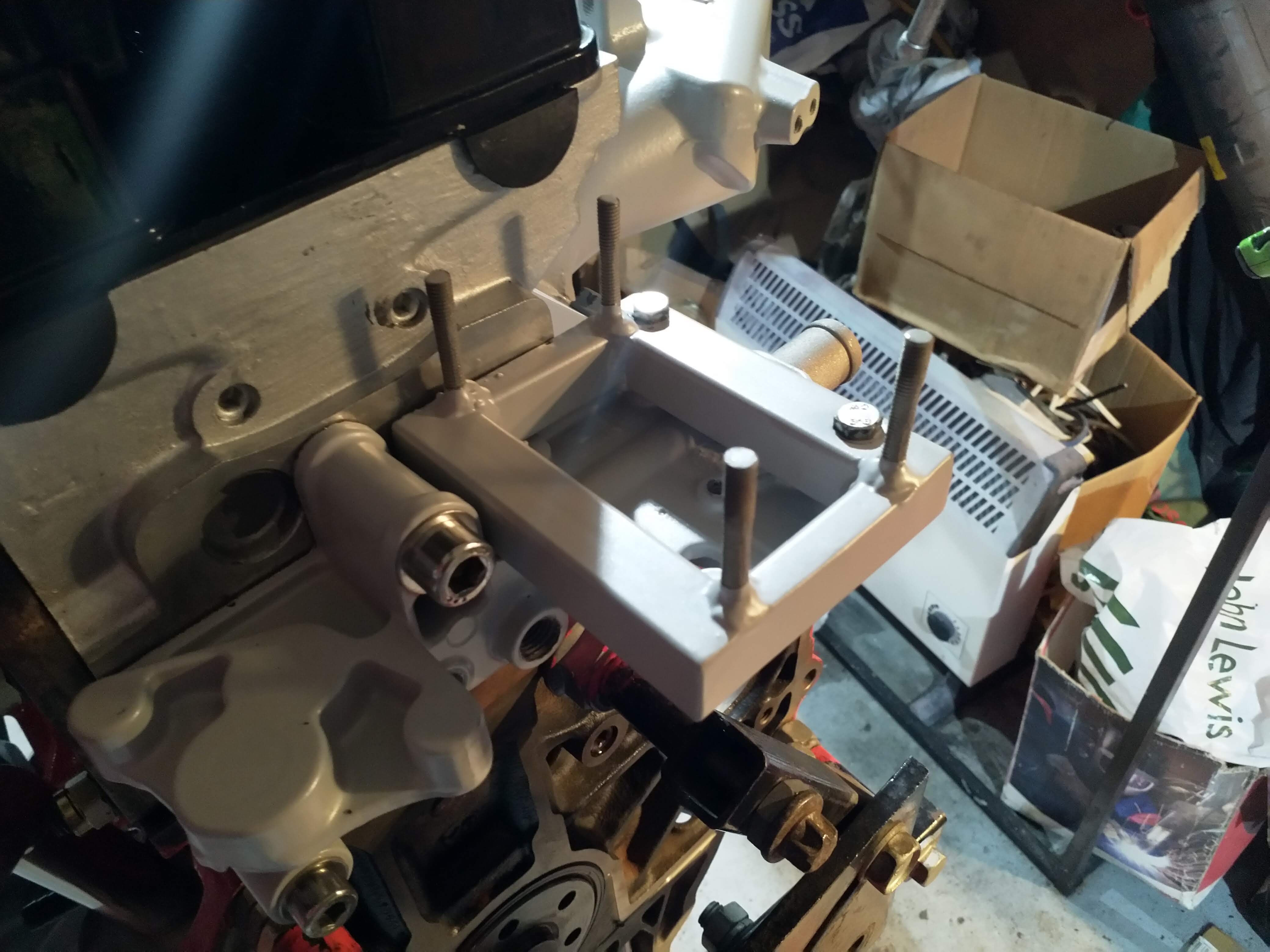

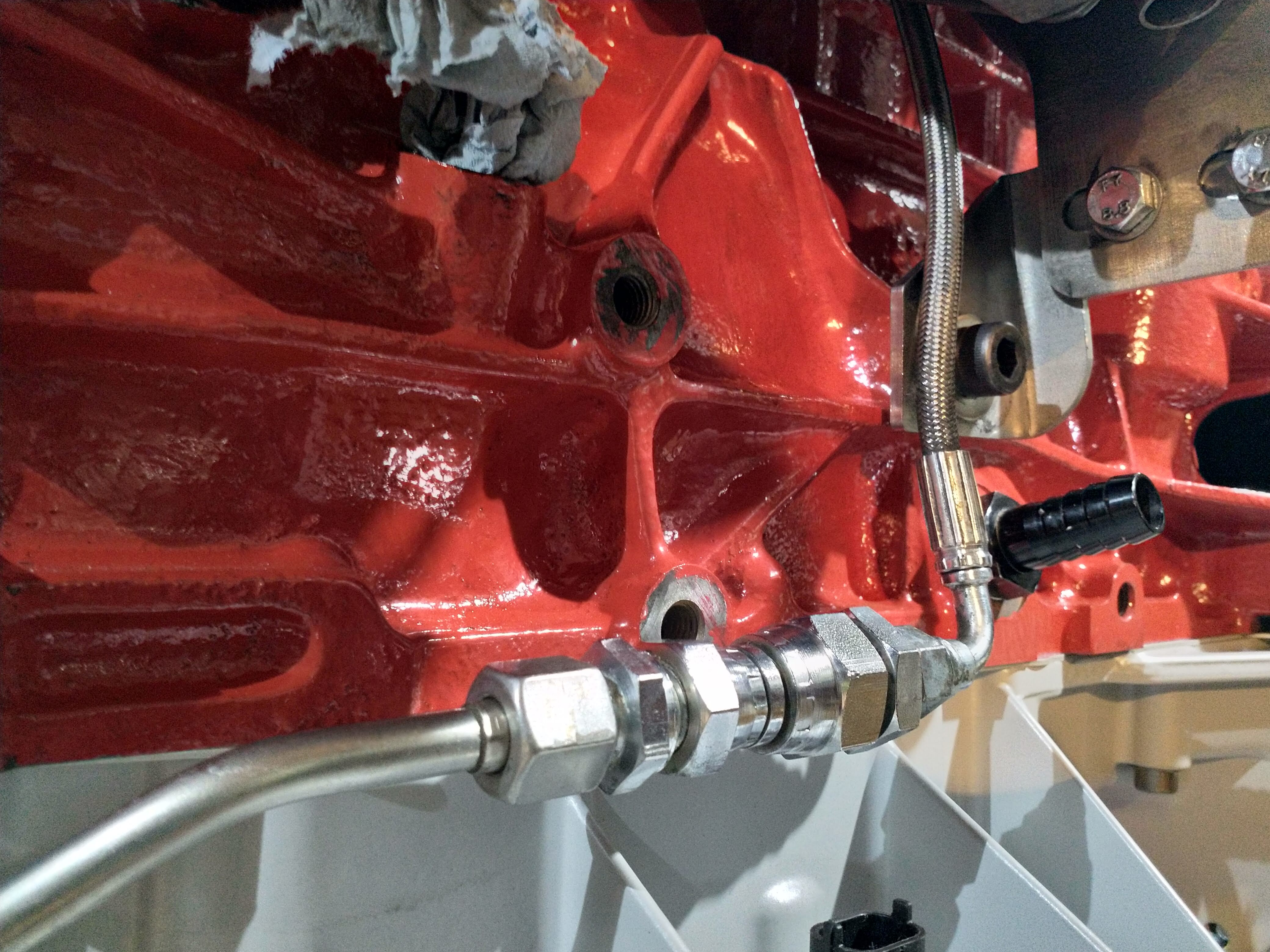

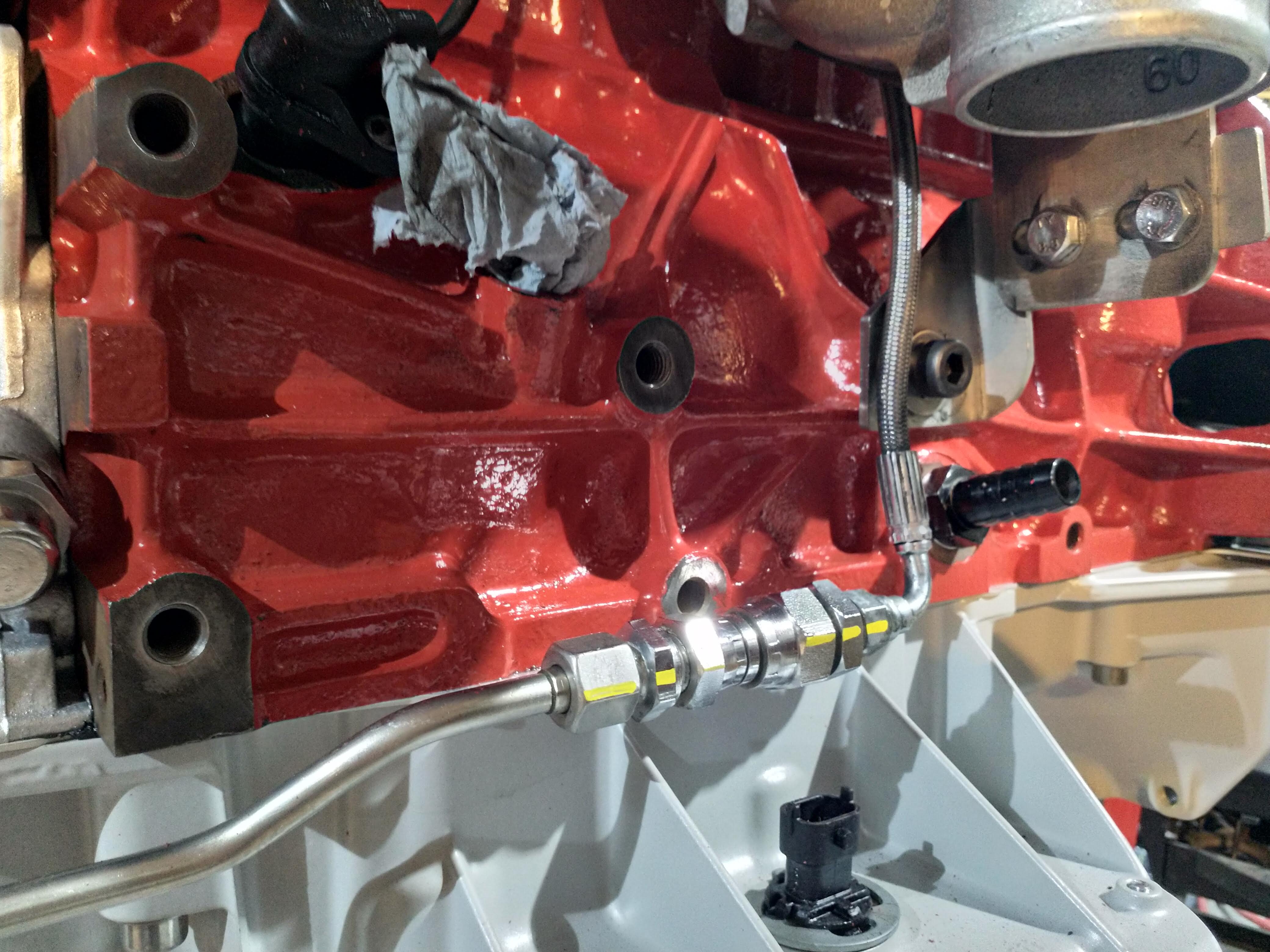

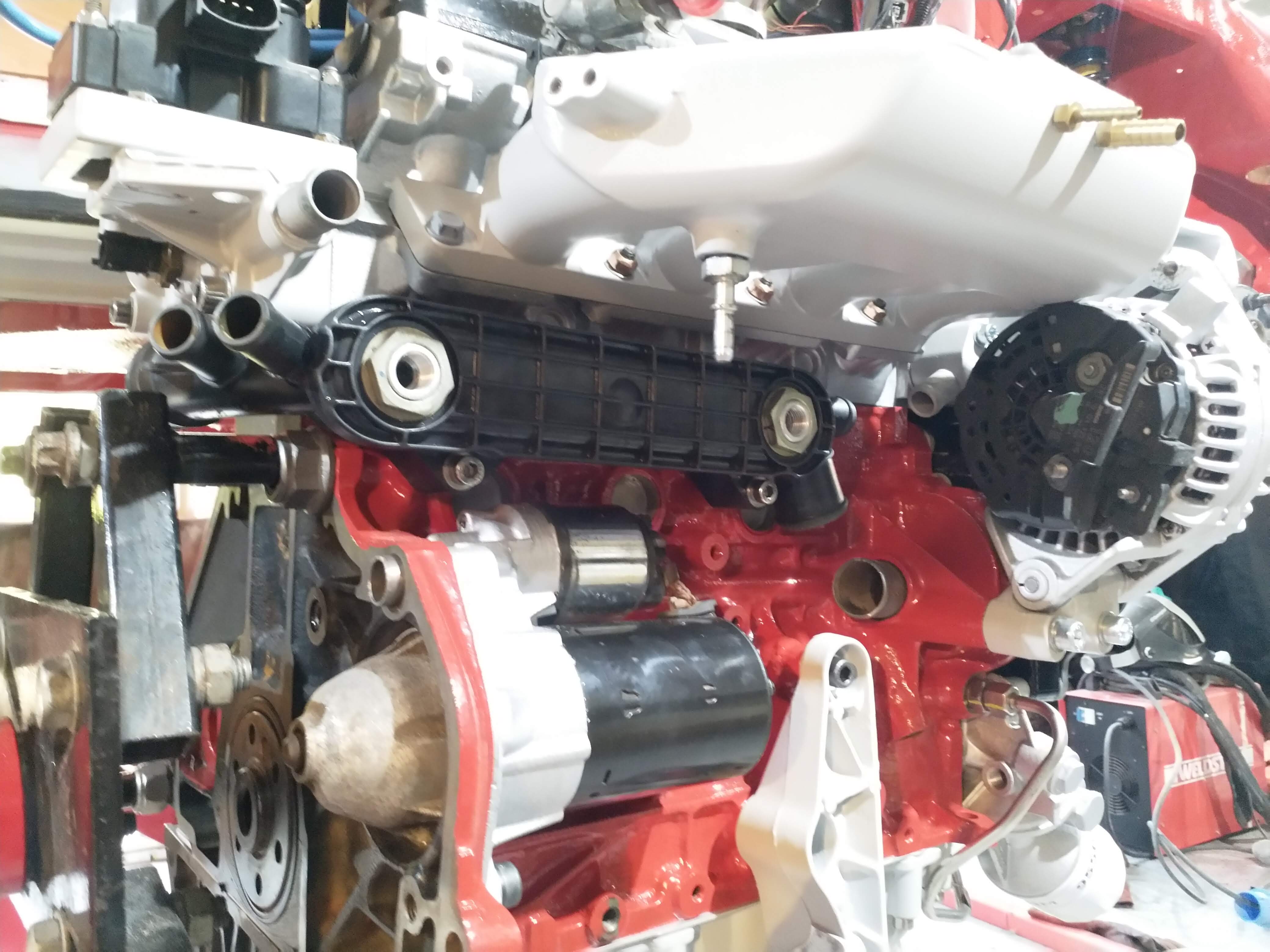

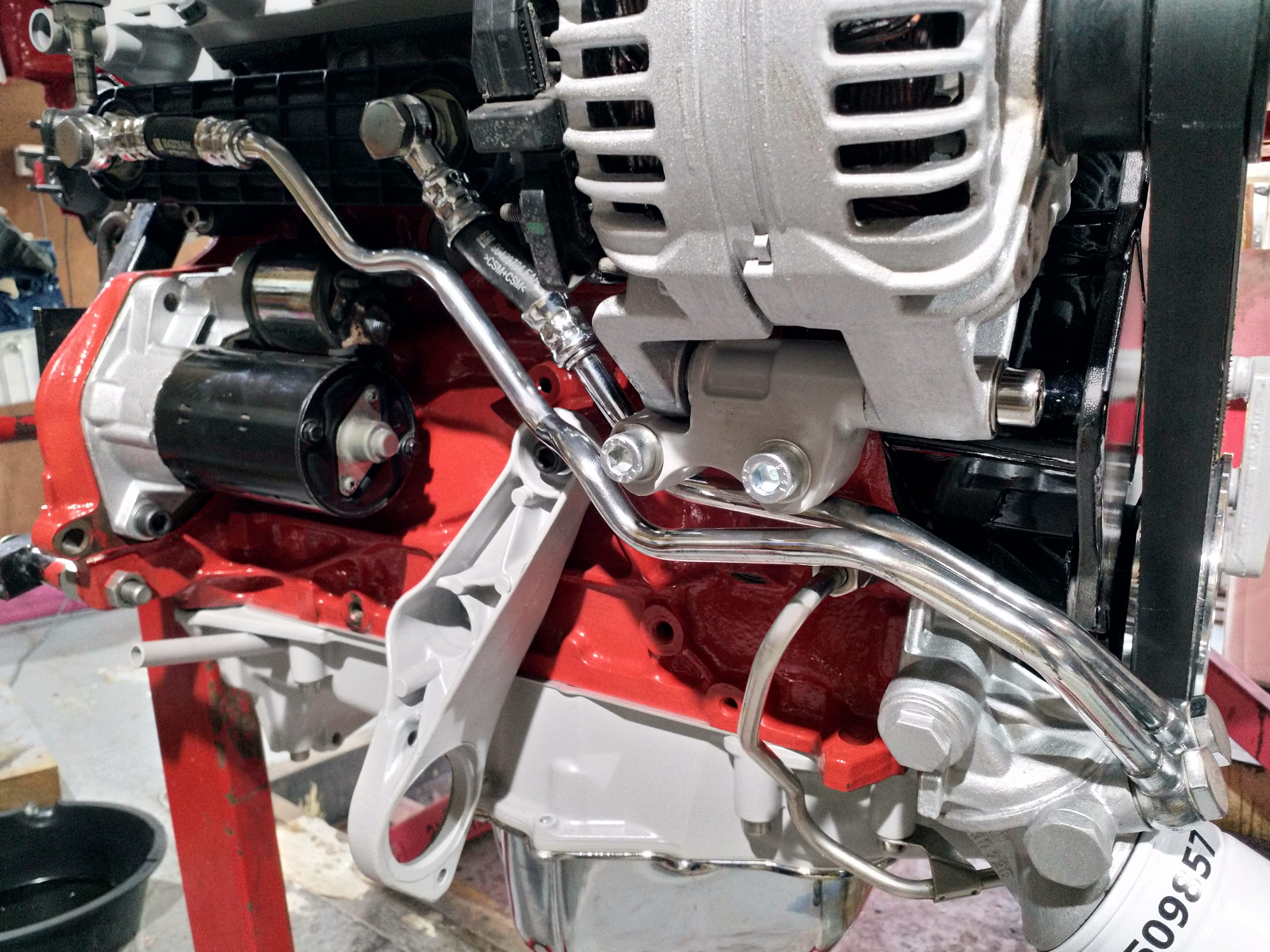

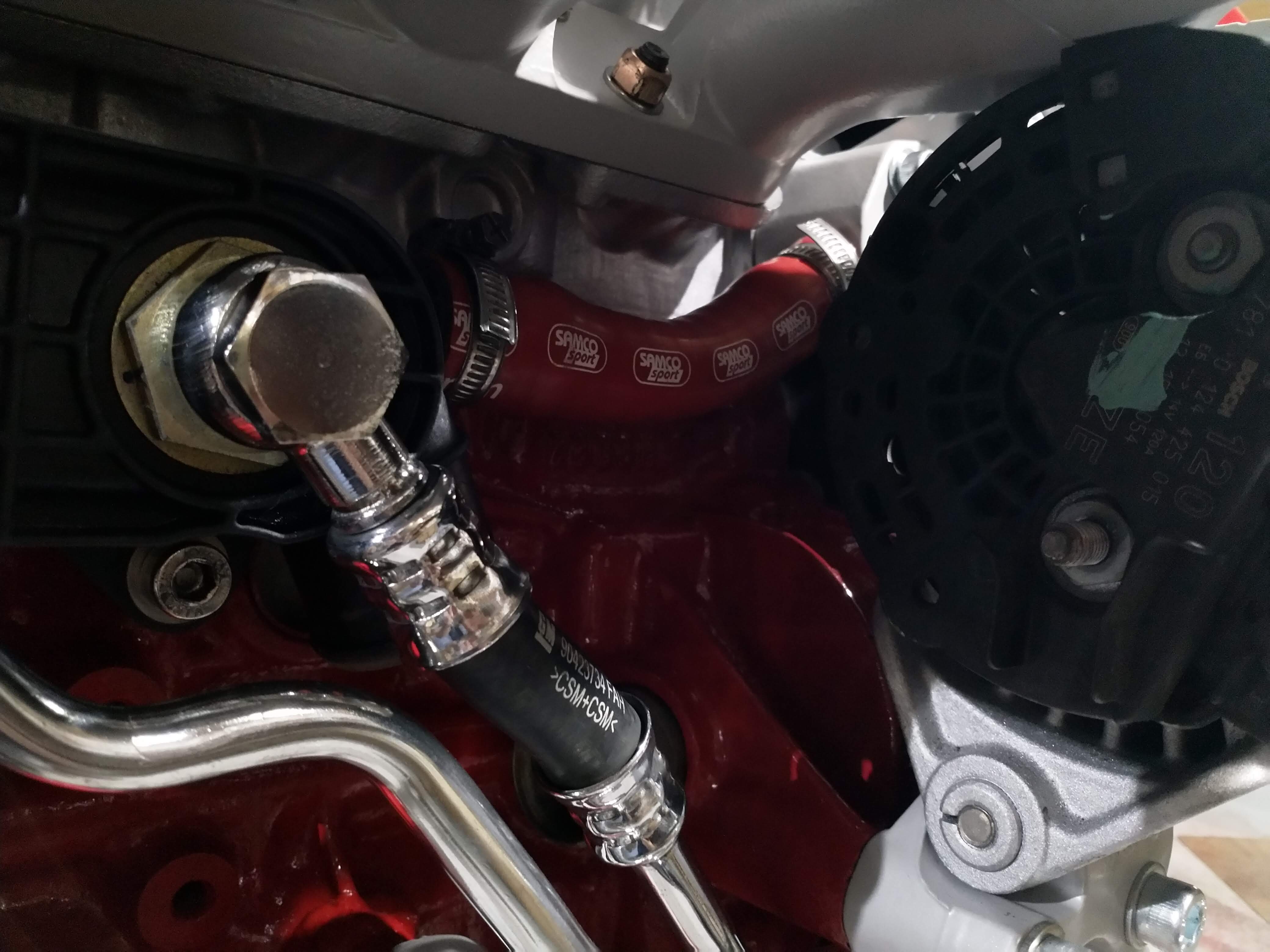

Headgasket on, new head dowels, new oil pump dowels, Oil pump on.

Arp head studs in. I've always wanted to run these!

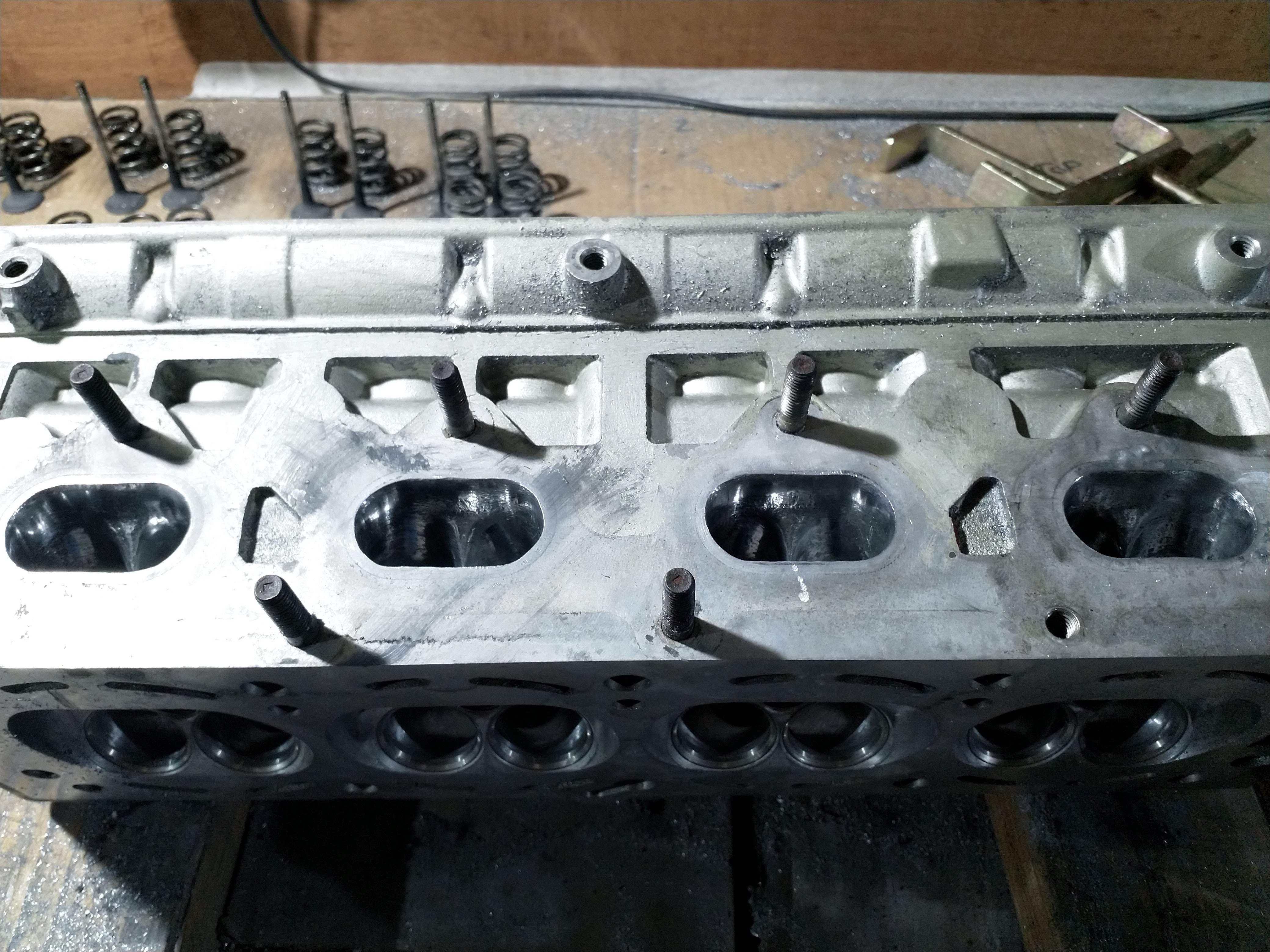

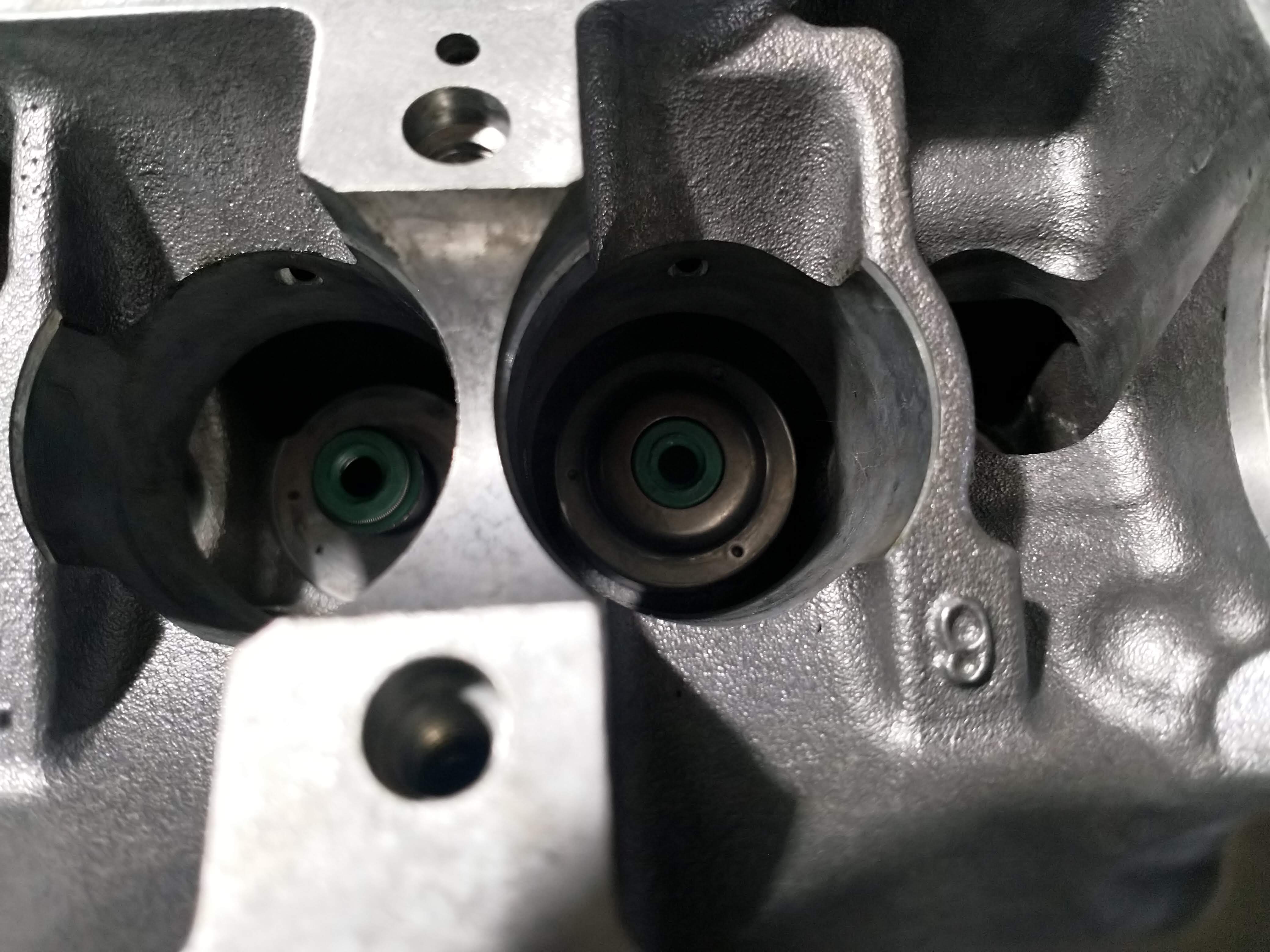

Cylinder head on!

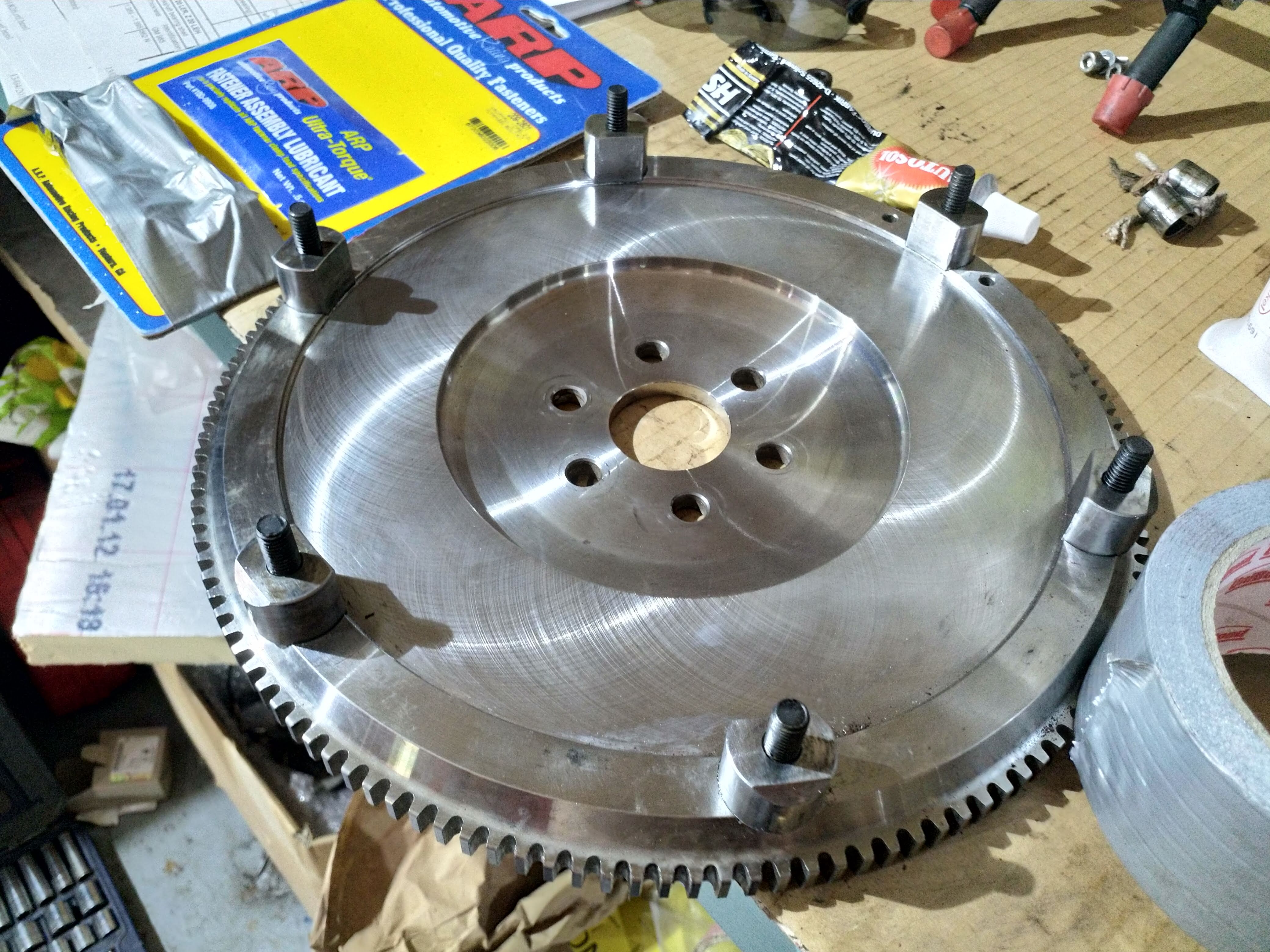

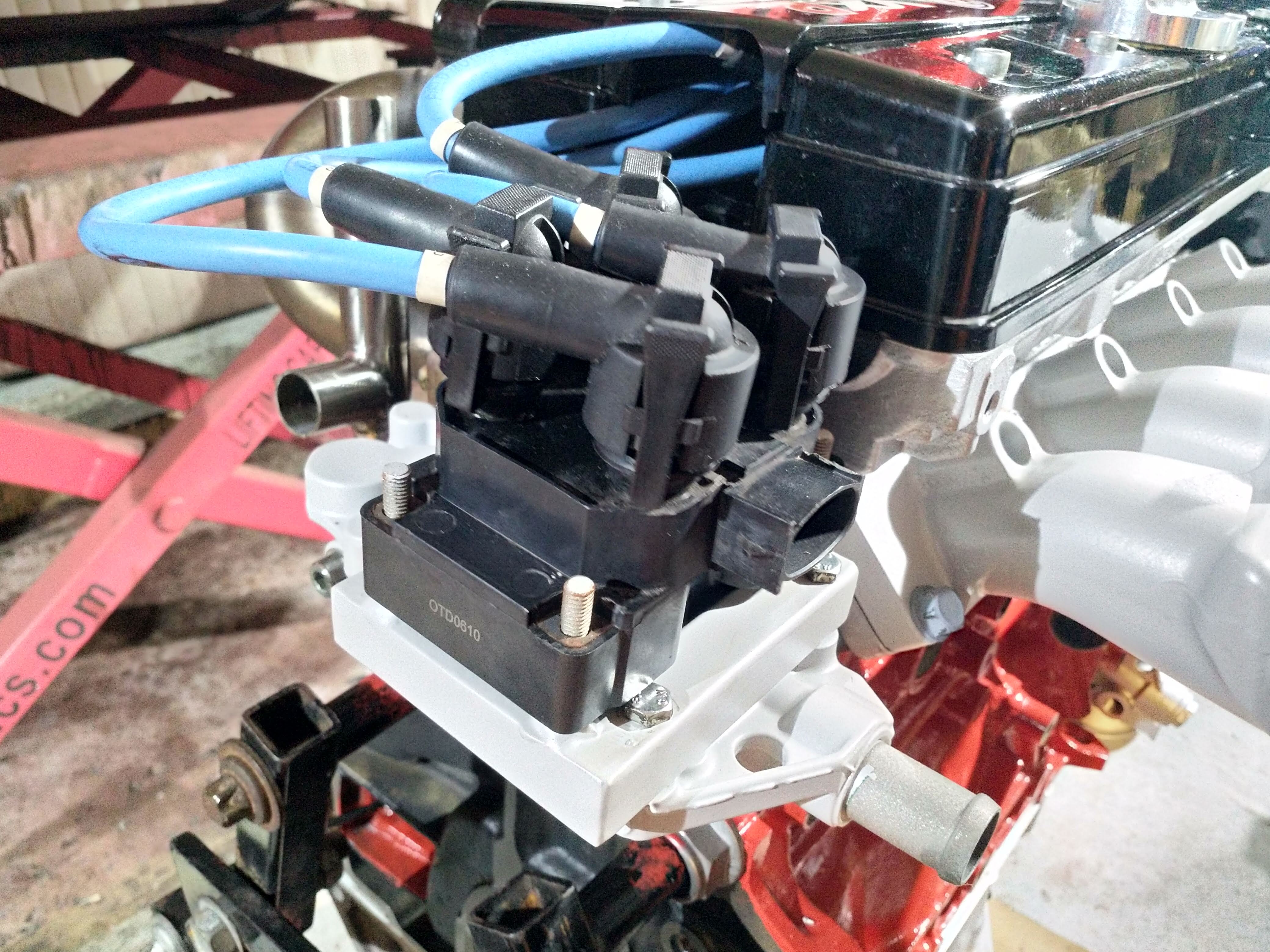

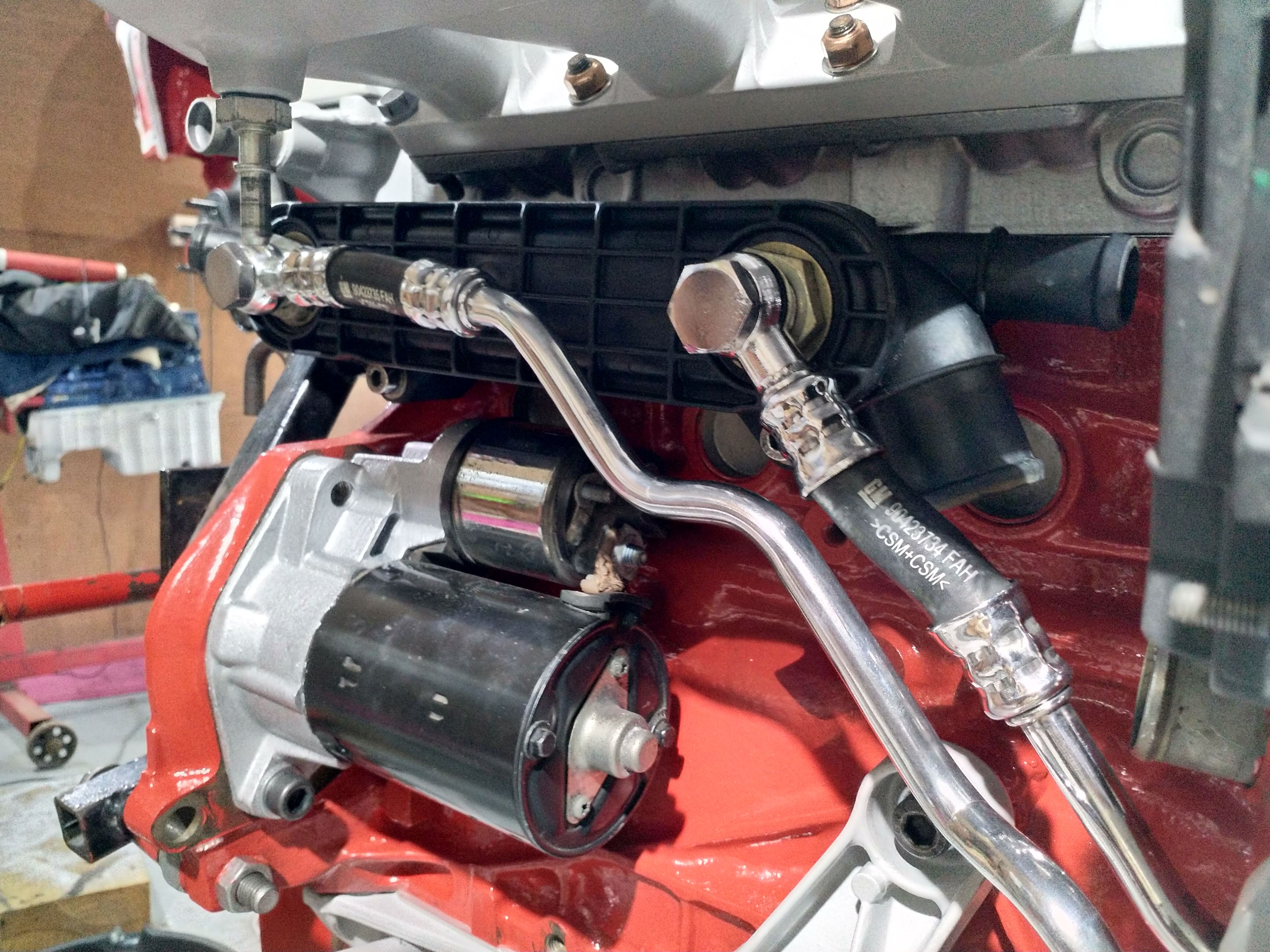

Had a bit of nightmare with this actually. Not really a biggy but i noticed that the arp instructions for both the conrod bolts and headstuds no longer include ( work the fasterner and up and down 3 times to allow the lube to be spread evenly)

So me being an OCD bugger, I felt i needed to search the internet and see if It existed still

FYI, it doesn't.

But while searching I looked at the headstud instructions on ARP's website for generic kits and it mentioned ' Fit the washers with the chamfer

facing up'

There was no mention of that in the instruction I got with mine! Luckily i hadn't tightened the head at all due to searching for the other info, so i managed to remove all the washer again, barely barely noticable but it is there. You can fell one side of the washer is sharp and the other isn't.

My poor OCD would of had a melt down if i had found that further down the line!

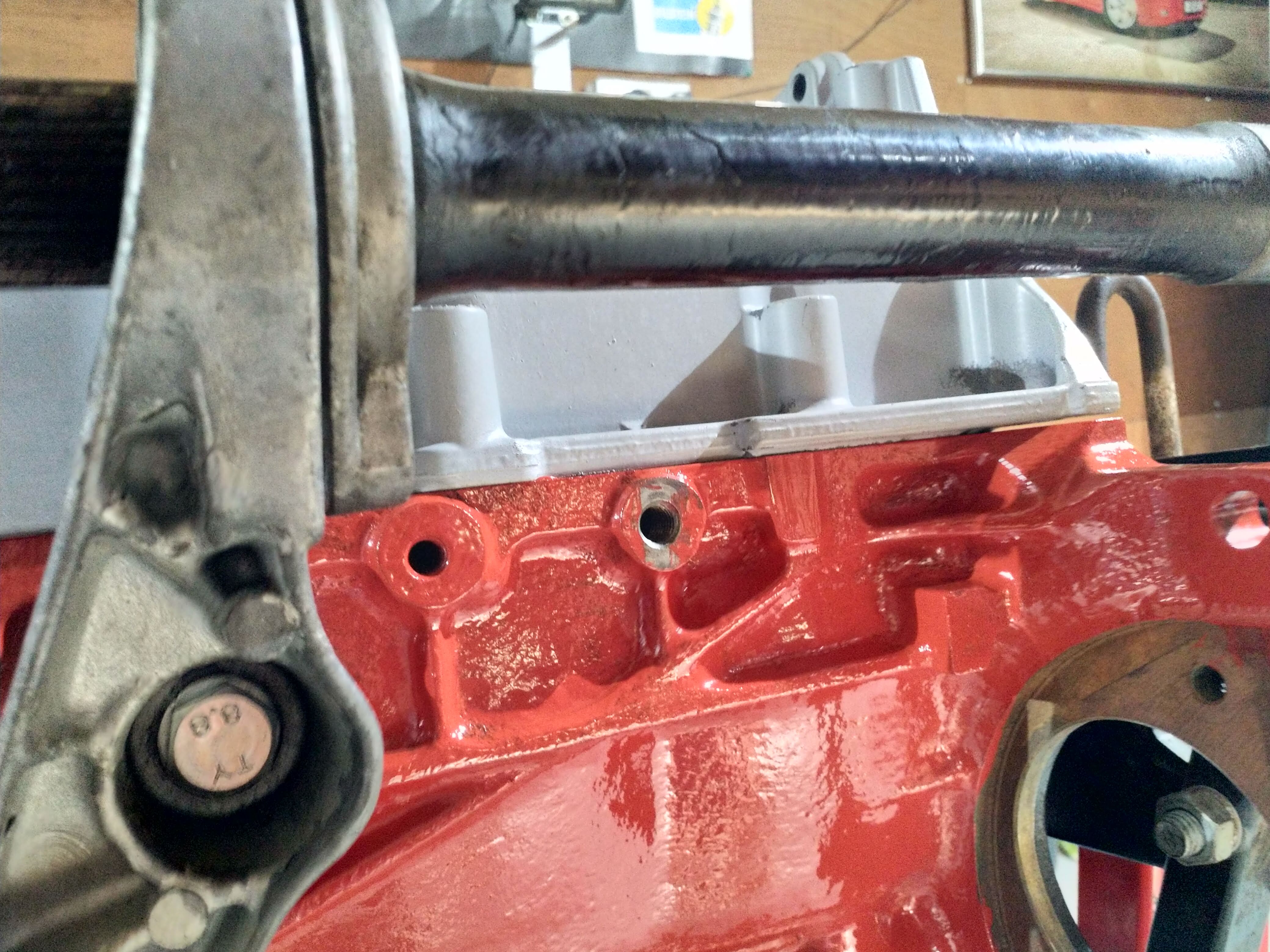

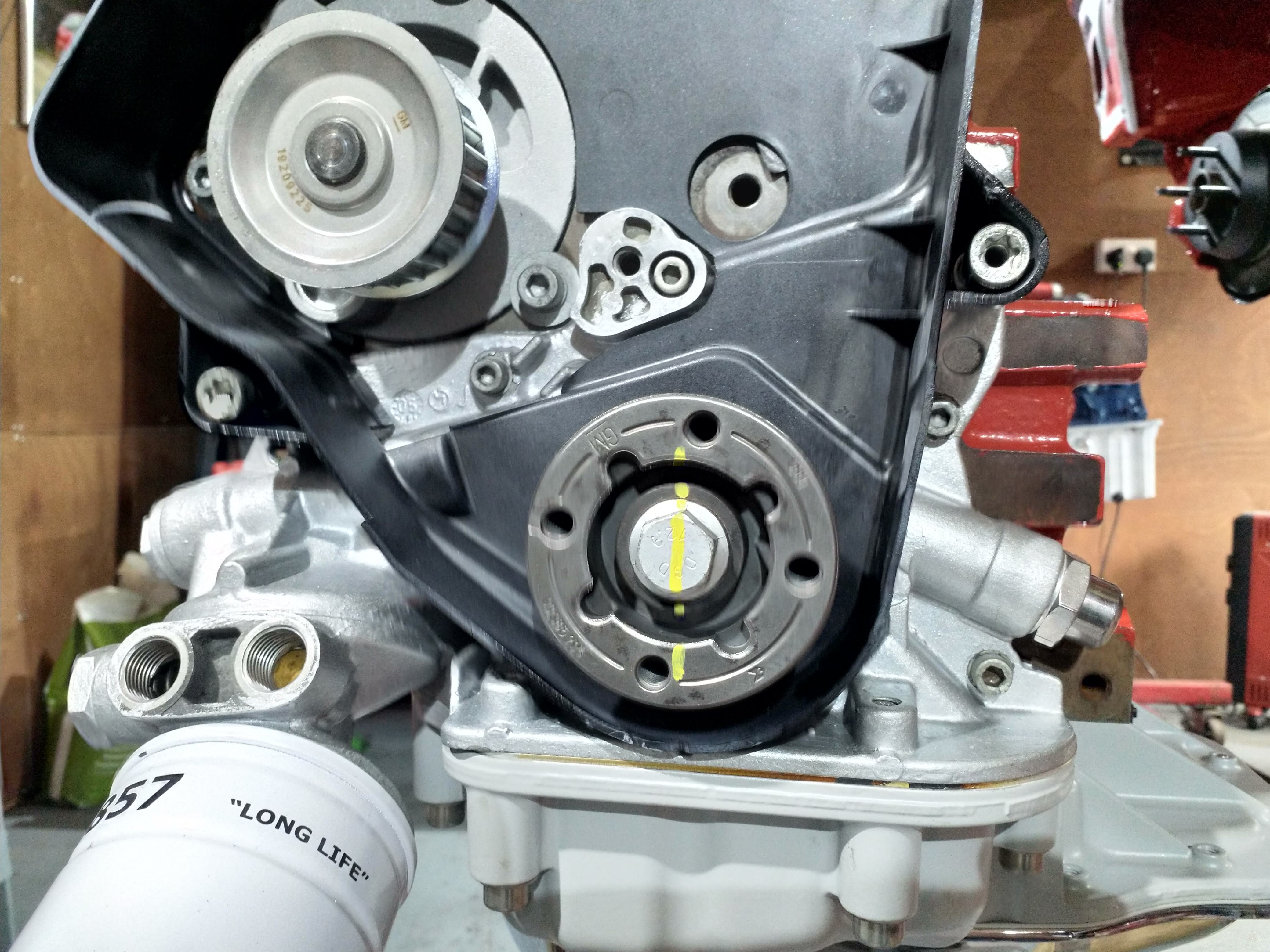

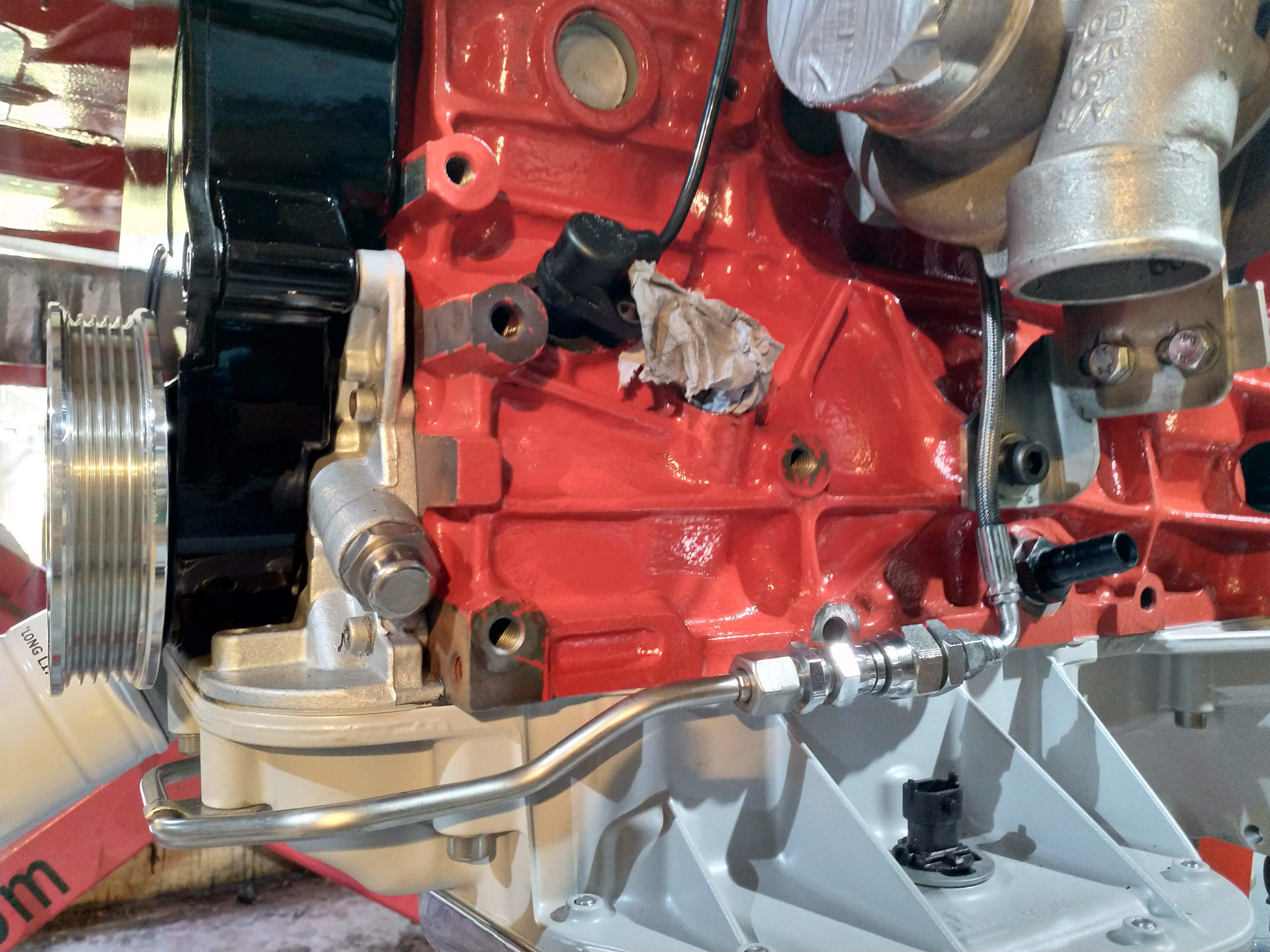

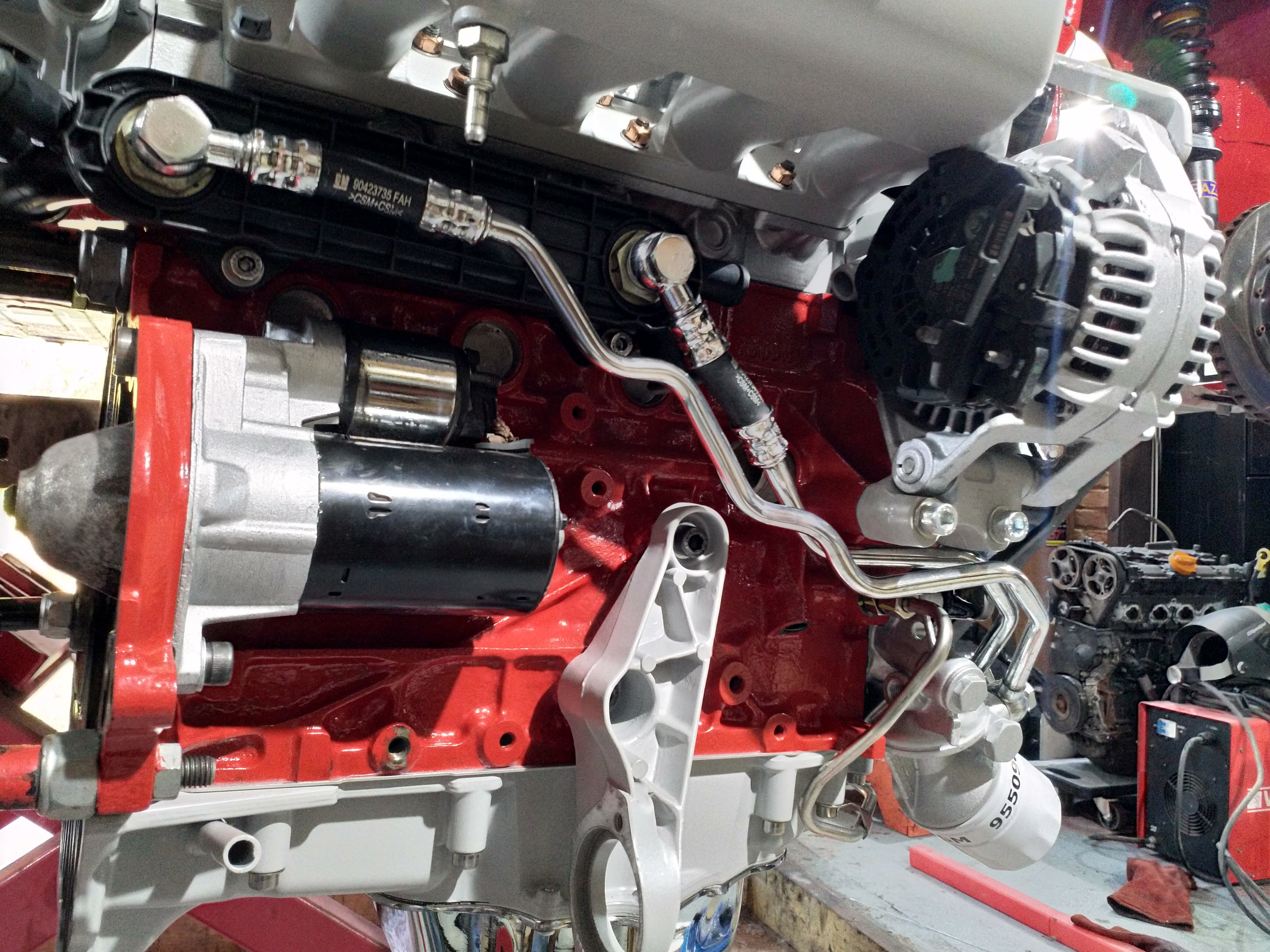

All good though, next crank seal in (easier to do this with the pump on as you can use a 36mm socket and long bolt in the crank and press the seal in flush with a bit of grease to help)

Rear timing cover outside for painting, I did this in 2k from a gun on my drive

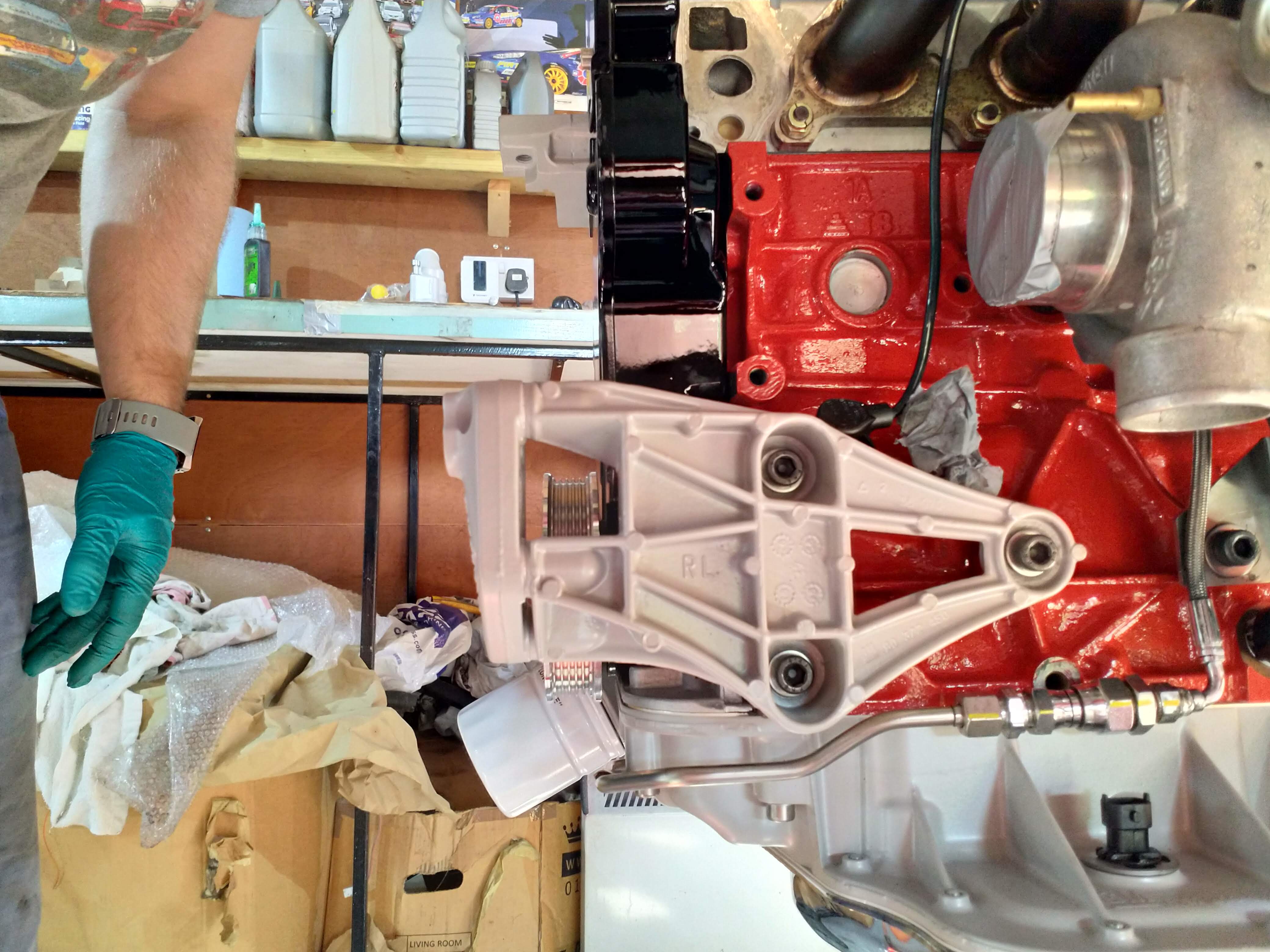

in between coats, sump on, all the powder coat goodness is appearing now. I was sure to clean all mating surfaces of powder coat and clean everything incase of sand etc

tappets in

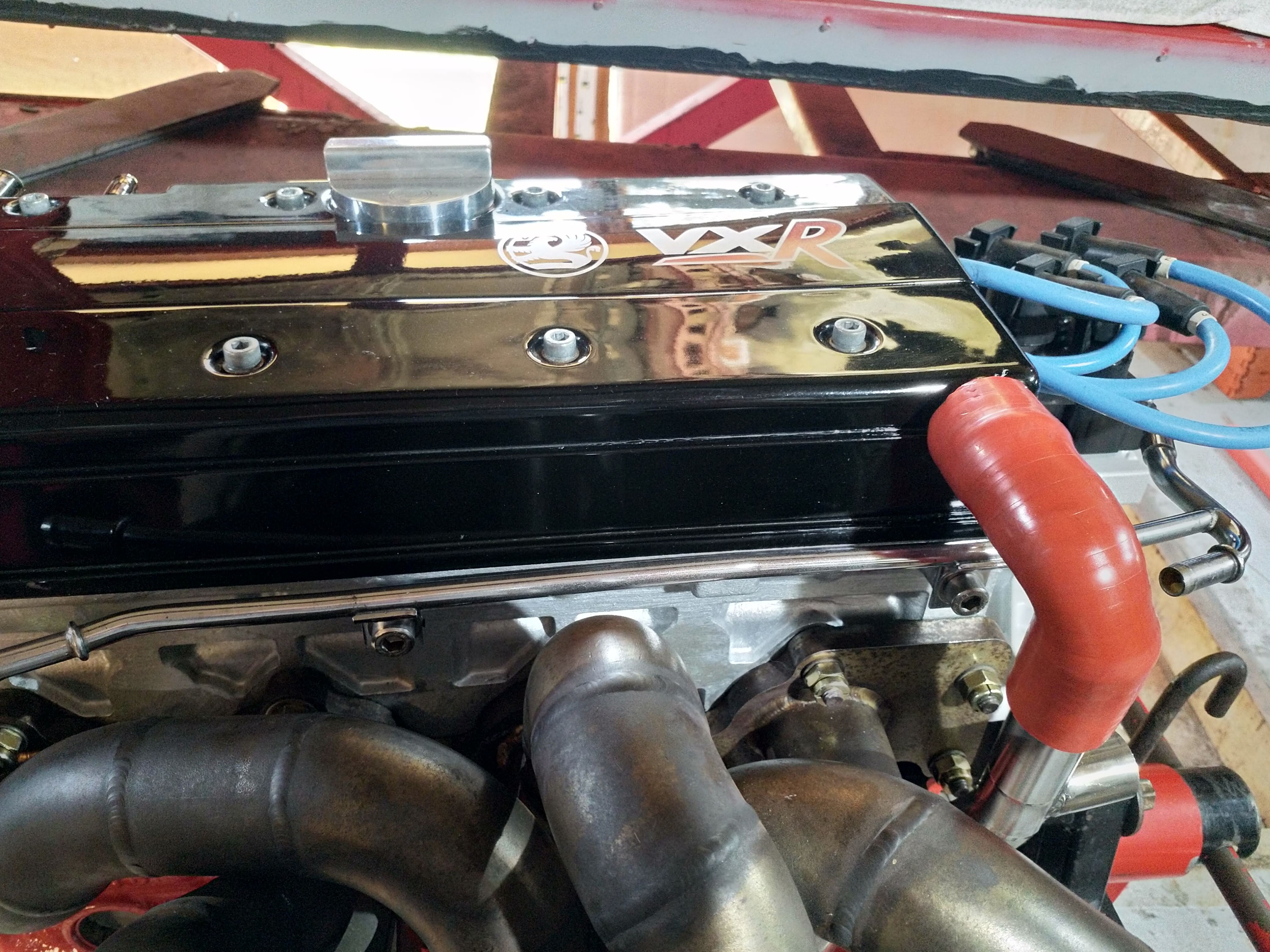

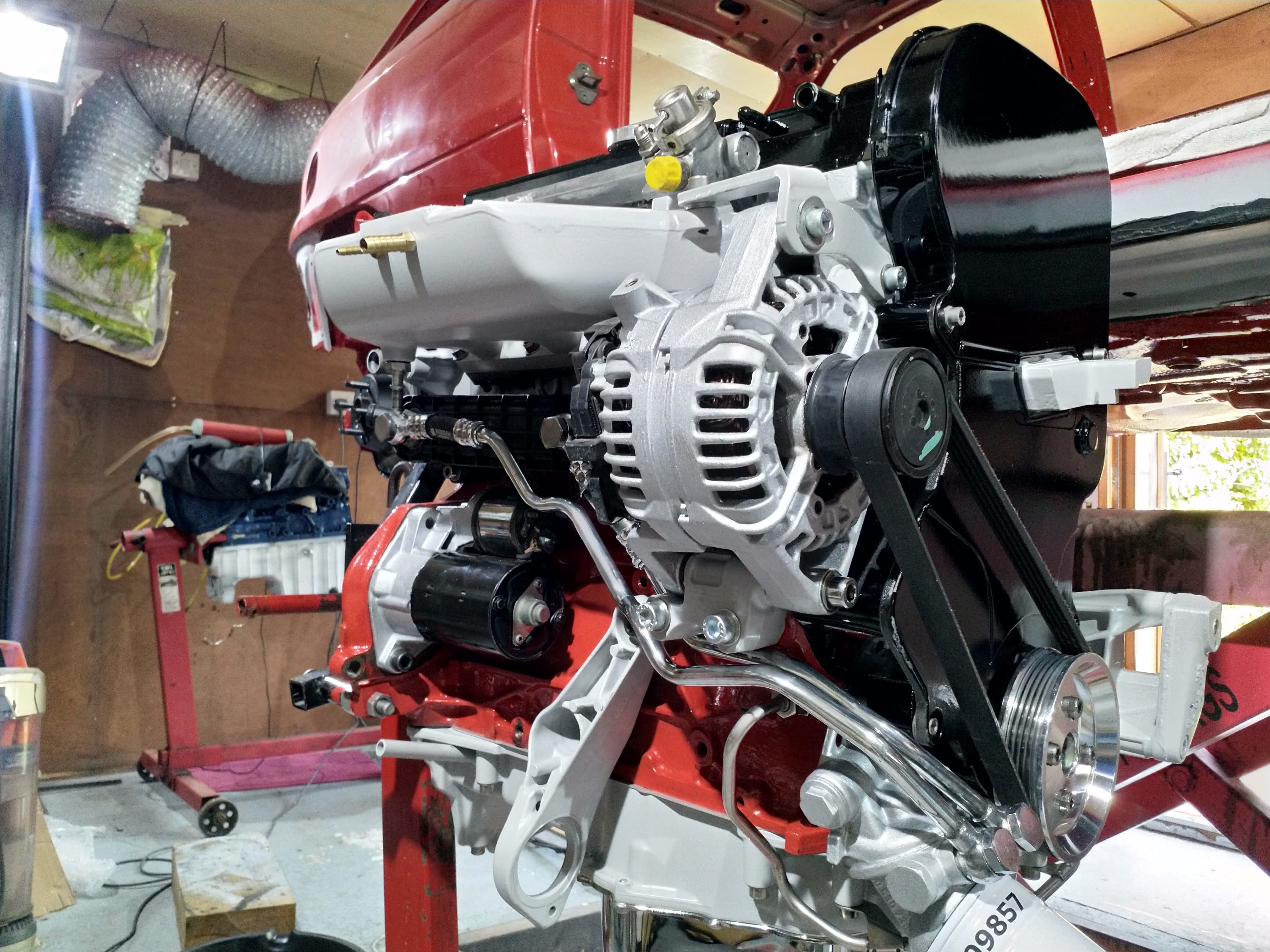

Piper ultimate road cams going in

timing cover all done, came out brilliantly haha

Cover on (careful to hook it behind the water pump incase the waster pump need to be changed!) Crank pulley on, new bolt, torqued up

water outlet housing

Timing belt and cam pulleys on!

Look like a real engine now!

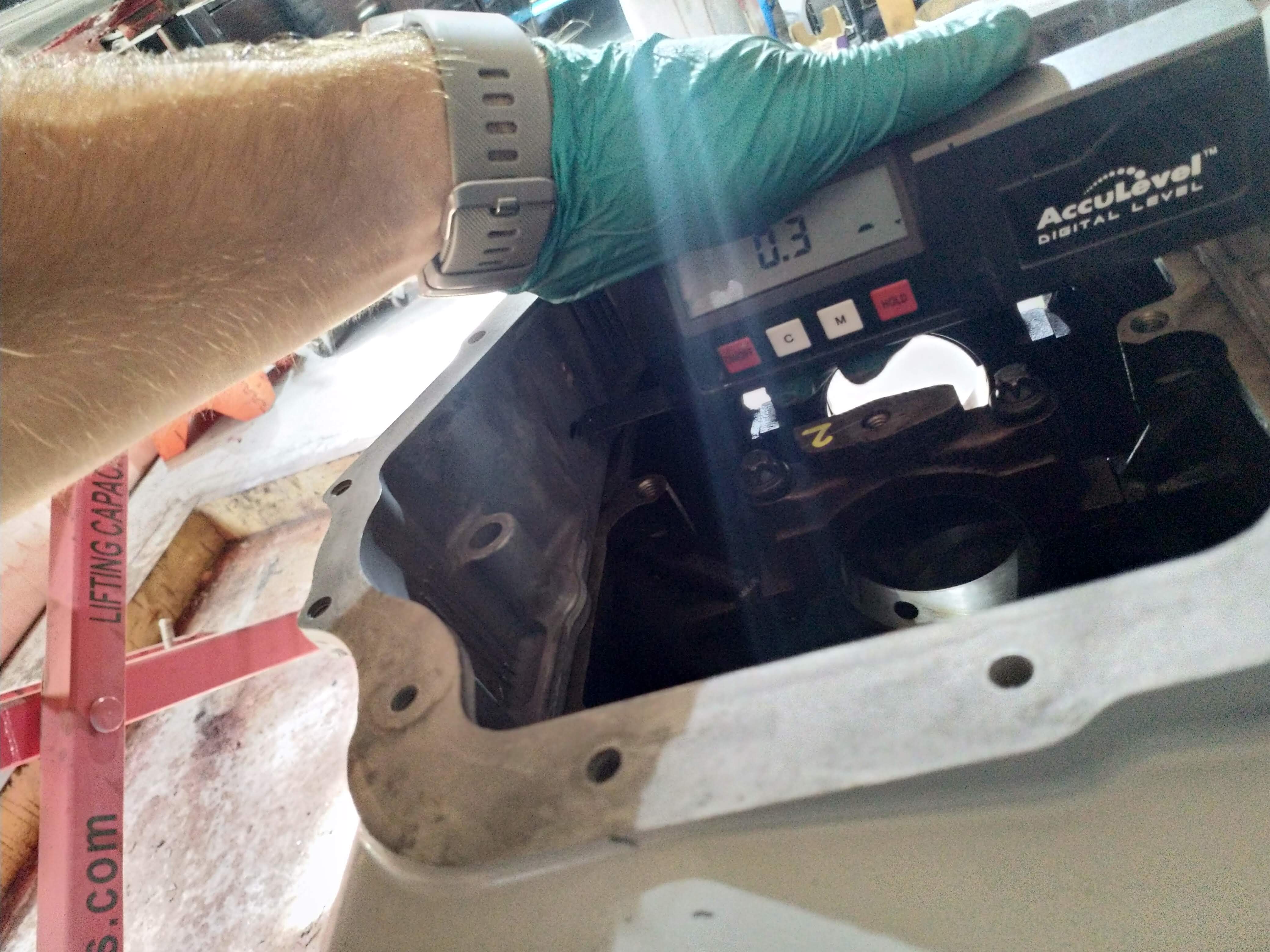

Next I checked the cam timing. I didn't get any pictures of this, but basically It is to check the cams are where they should be and I don't need to buy vernier pulleys.

Very briefly.....

Use a DTI gauge to find tdc, but also the piston is at tdc for a fair few degrees, so by finding the duration of TDC in degrees, you find absolute TDC.

Fit a timing disc with a pointer and put this at 0 degrees

Then Put a dti on the bucket and find full lift ( when the bucket is furthest down and valve full open)

Measure this 0.10mm before and after full lift, again the valve will be at full lift for a certain duration

Check on what angle of the crank full lift opening and full lift closing happens

find the average of these measurements and that will give you your degrees of full lift and check this against the cam specs.

My both my cam specs are full lift at 110 degrees ( after TDC and BDC )

Now each tooth on the pulley wheel is worth 6 degrees I was told

My cams came out at 108.5 degrees and 108.25 degrees. Which means they are a third of a tooth out

I'll take that. Basically perfect. Certainly not enough to chase in a turbo car as it will make so little difference, the cost of new pullies just isn't worth it.

So i'm a happy bunny, engine turns over, everything went together well, bit push and I can get this done!

Look forward to build pics

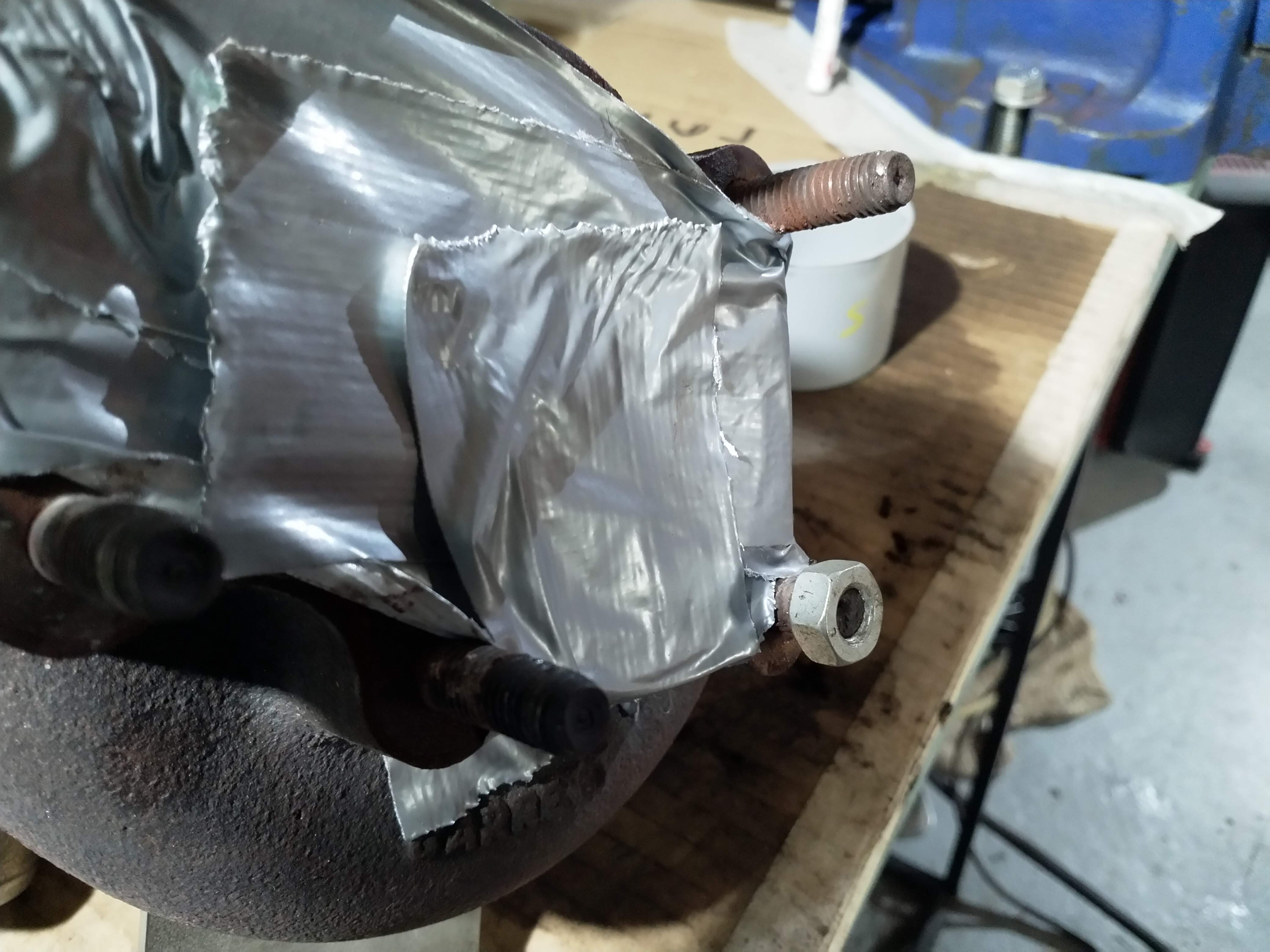

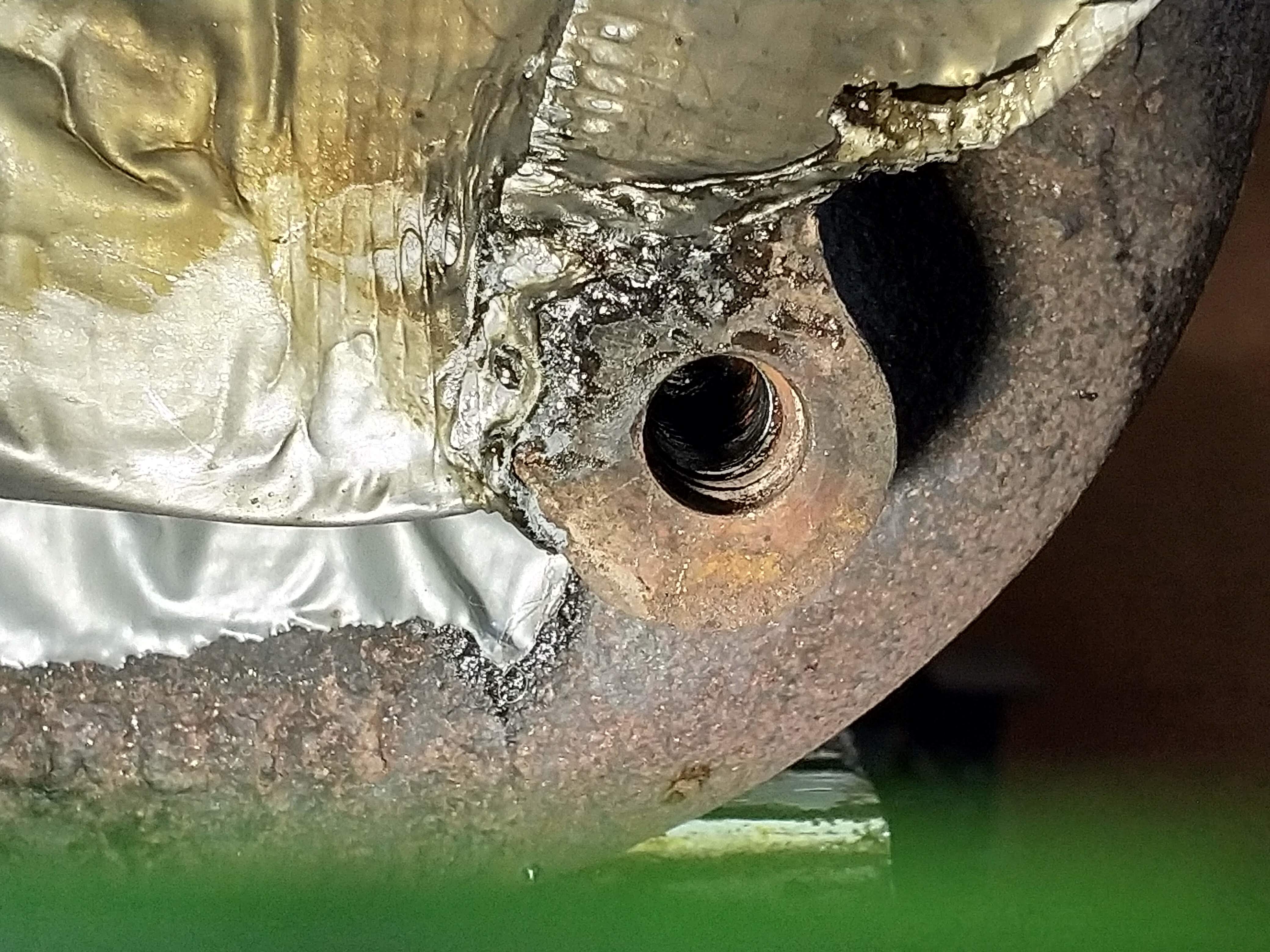

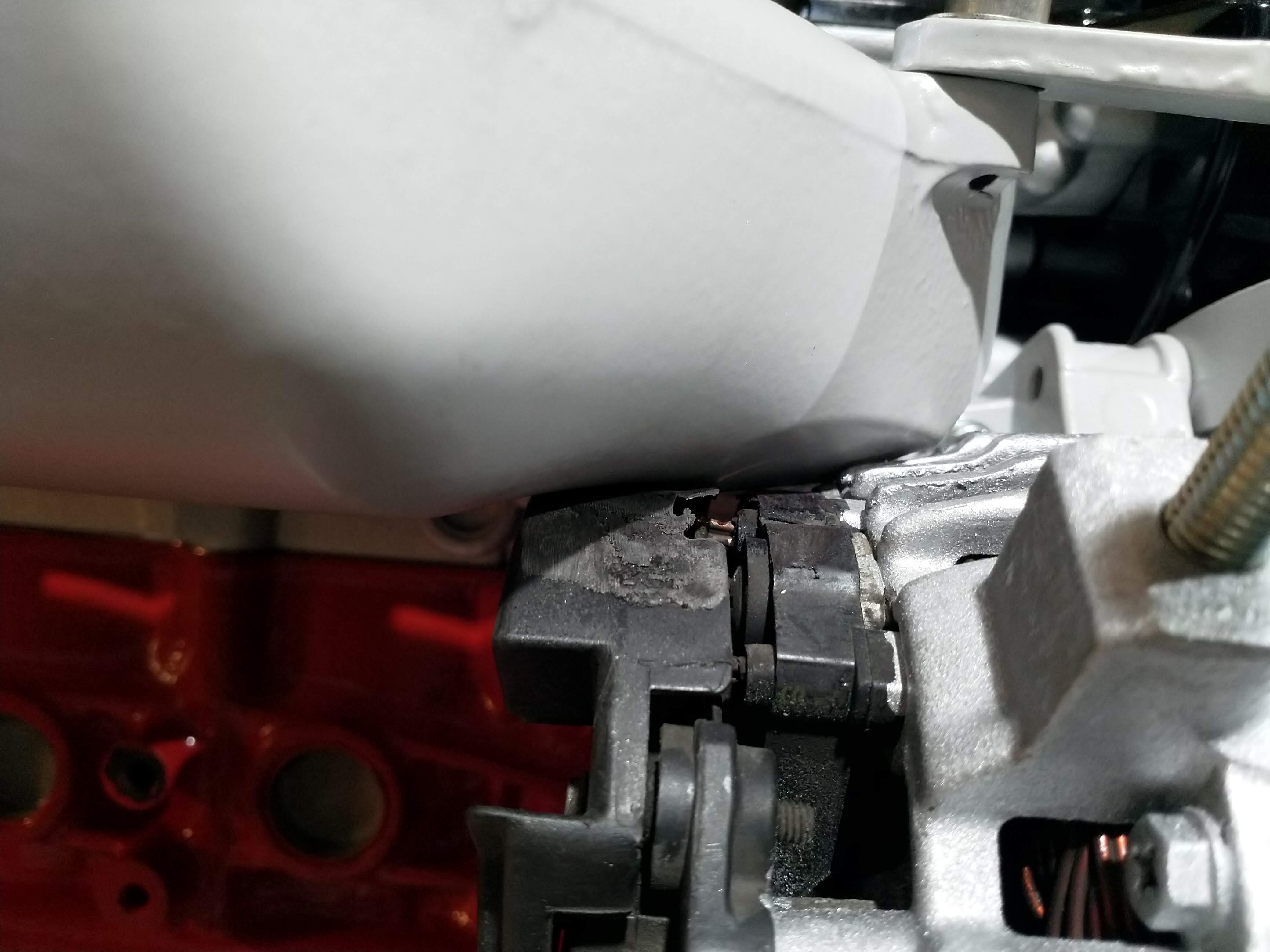

next thing to sort the snapper turbo stud, I have honestly put this welder away 10 times this project haha

next thing to sort the snapper turbo stud, I have honestly put this welder away 10 times this project haha