Bit of an update, I've always wanted another boot light in the astra, proper random I know but always thought the OE one was too small and cause I have a nice boot build, I want to show it off lol.

Now U can't actually cut the shell in the same place but on the other side, cause that is where the fuel filler panel is! So the other option is a stick on LED

cut down the back of the lamp so its doesn't hold a bulb, but will still clip into the trim

job done

happy with that, next up I had a chap come over who I found on facebook who was willing to fit my rear window to the astra, I could of fitted the window myself, but for the sake of chucking someone some cash, he has all the gear, the sealant, the window suckers etc. I would rather just pay someone and it be right!

After booking him in, I tried to fit the front window trim around the windscreen, turned out the previous person has used to much sealant, and put the window in slightly pissed aswell! So I couldnt get the bloody window seal in!

So i ended up paying this chap to cut the front window out, clean everything, fit the new seal and put the windscreen back in! Nightmare, but all sorted now

well happy with that, another piece of the puzzle!

Next up, bluetac on the wing to make where the rivets need to go for the side skirt clips

then just pushed through the bluetac with a pointer to mark the paint and job done. Ready for drilling and rivets.

Next up was polish the quarter, funnily enough started polishing the quarter and noticed this

Must of been where I didn't flat the quarter properly, looked like I had flatted through the orange peel, but missed this bit along the seam, I was probably being too careful as It is near the crease in the quarter and didn't want to rub through!

Also found this where I has scrtched the clear coat with the edge of the stanley blade gettin rid of a run!

So on these areas I went back through the motions of 2000,2500,3000 grit and got rid of them, polished up and second time, much much better!

With that all done, mocked up the side skirts, marked the holes, drilled, painted and then slide the riv nuts in ready for the skirts to go on!

At this point realised I don't have enough Side skirt clips! Annoying! So just trying to track some down!

With the quarter flatted though, I can fit the rear bumper, after some prep.

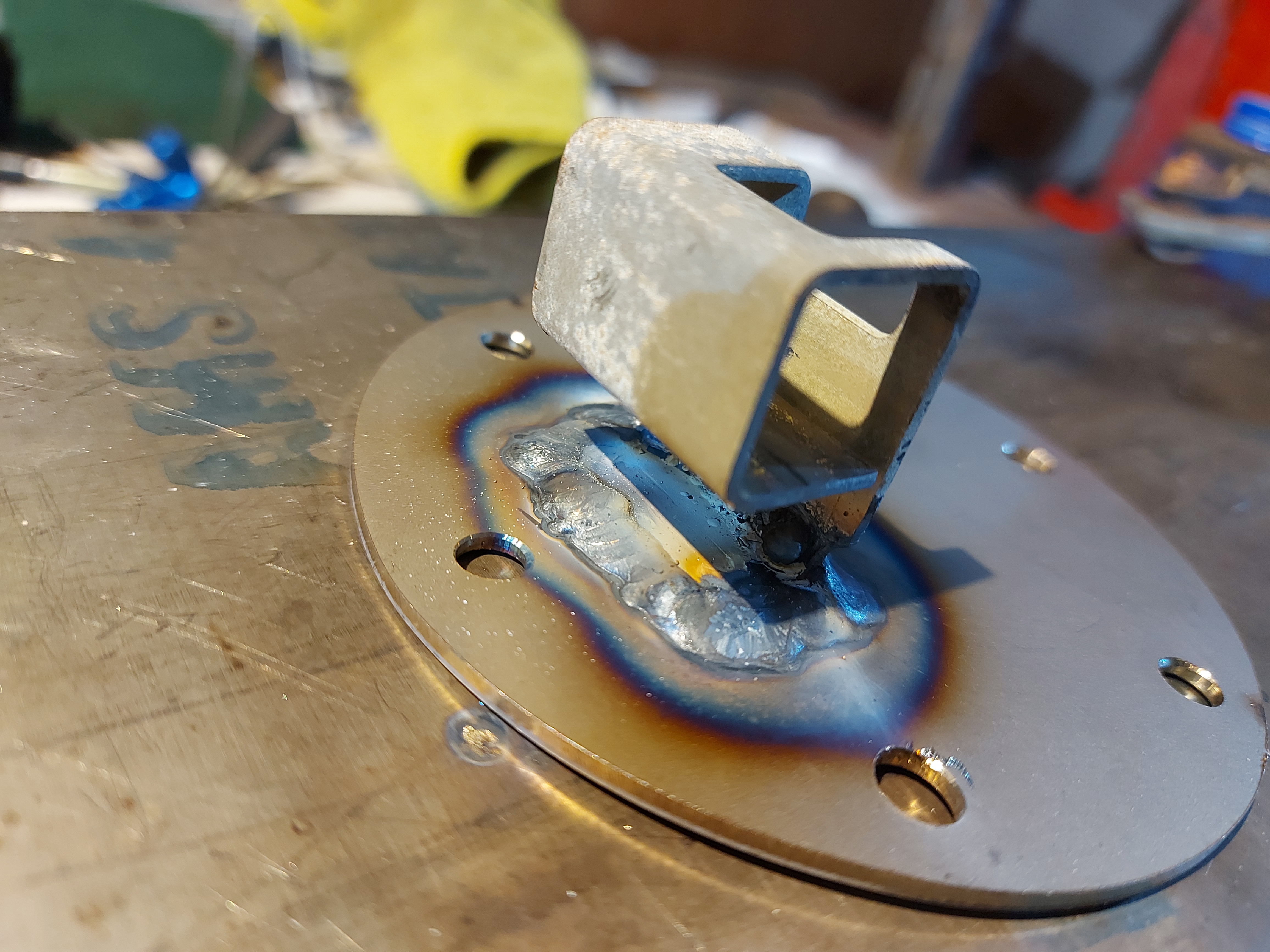

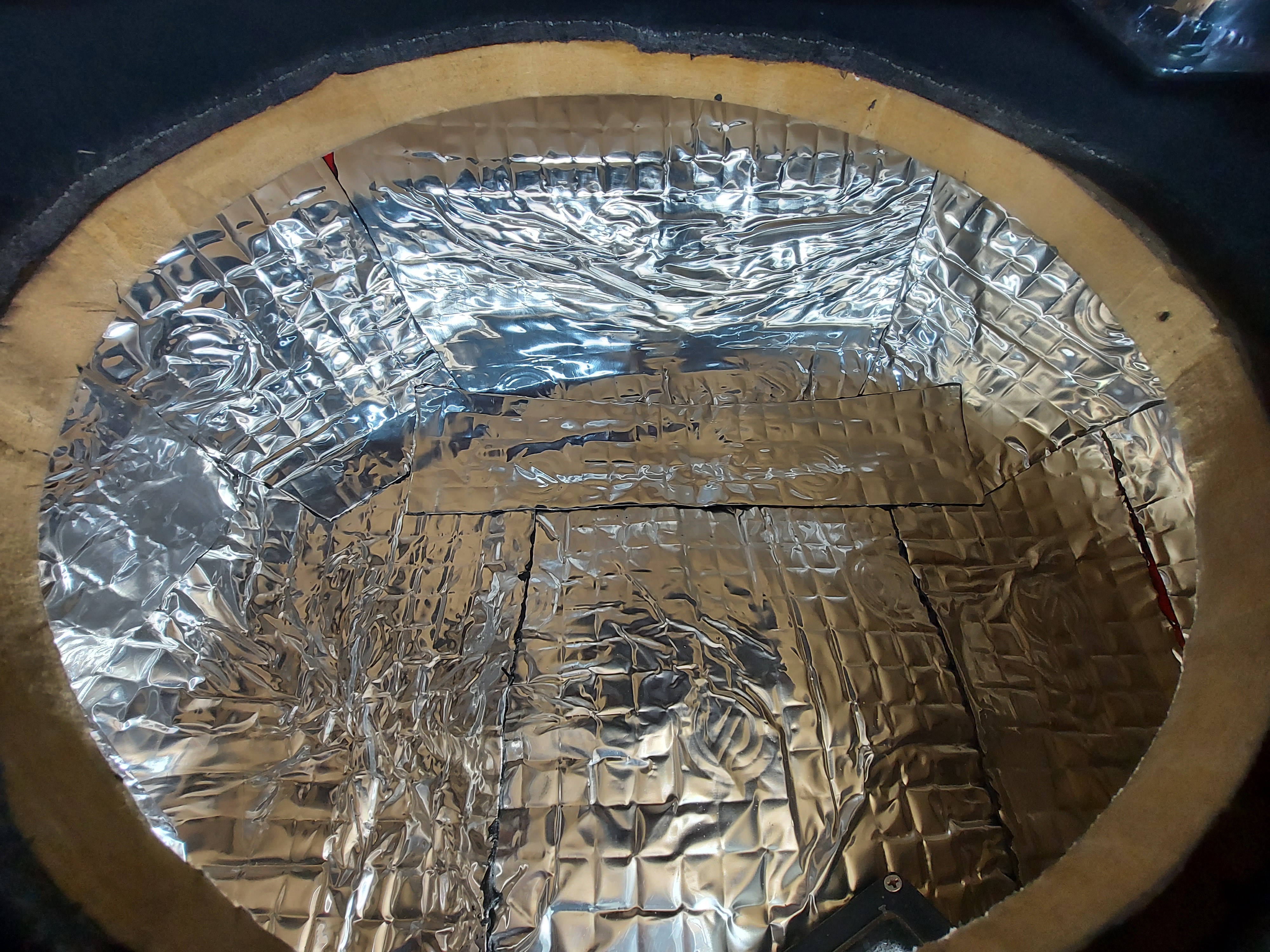

First things first, heat protection to stop the back box melting the bumper again! Zircoflex stick on stuff, I Melted the bumper, then ran this and it never got any worse so it works!

So to protect my new paint work I bought myself a roll of PPF. Everyone is badgering on about this stuff now days and although I won't be fitting big sheets of it across my front bumper but I bought some to protect certain bits and bobs.

So the first part to fit it to is the 'built in mudflaps' which is probably more of a strengthing part of the bumper to keep its shape, but this part gets pummled with stones and end up black again!

SO cut a sheet off

funnily enough the sheet isn't quite big enough lol

applied the sheet, you can see the texture of the plastic where it isn't smooth from years of stone chips, I never bothered trying to smooth it out of anything, but that no airbubbles, just that textured plastic look.

little cut out for the triangle

used the hot air gun to fold the corners round, waited for it too cool down then cut the excess off with a stanley blade! Actually looks really good from head on, seamless!

Both side done

New foam fitted to the top, no idea why this is on the bumper, but it is so I replaced it for new haha

bumper on with ' as bright as the sun' number plate lamps lol

led tail lights and number plate lights...

their a bit bright haha

Looking good though

Looking good though

Looking good though

I can only imagine I did!!! I must of had the right arse haha

I can only imagine I did!!! I must of had the right arse haha

done it's job! Sucked them out with brake bleeder.

done it's job! Sucked them out with brake bleeder.

.... well, apart from the front bumper and grill which just need running over with the mop as they didn't get sprayed.

.... well, apart from the front bumper and grill which just need running over with the mop as they didn't get sprayed.