So First of all i'll explain this thread, basically after the whole fiasco of it taking ages to get the mounts etc, we want to make sure they are correct as far as we are concerned. when the mounts arrived, me Todd and Nige got mounts off kev to be the 'guinea pigs' as such, and to check everything is ok for everyone

So now we have had a chance to have a play with the mounts and fit them and came across a few things that need adjustment for a better fit, and general things to improve them!

obviously we would like to point out, once u receive your mounts, u can actually just chuck them on, they do fit and are usable, we just want to point out our thoughts, and of course.

We as a club are not responsible for the fitment, mods, or life of the mounts. this is just us covering our ass basically, After all, you all knew what u were ordering before you paid its all up to you what you do, to receive your mounts, simply contact kev and he will post them to you!

its all up to you what you do, to receive your mounts, simply contact kev and he will post them to you!

Right so lets begin!

Chamfer

so as a few of realised straight from the offset, the mounts being flat makes them different to the standard mount, standard mount is curved to allow for the shape of the body, where as these are flat.

The negative side of this is with the mount being flat is that only the outside edge of the mount will make contact with the body, this means more pressure on the edges due to uneven weight spread, and more likely to have flex in the mount, reducing the life.

As a result, we recommend gettin the mounts machined down or using a file to make a shape which matches the body of the vehicle.

The mount is made from 10mm aluminum, and this should be come 7mm at the outer edge, to give a chamfer identical to that of the body of the car.

Mount Improvements

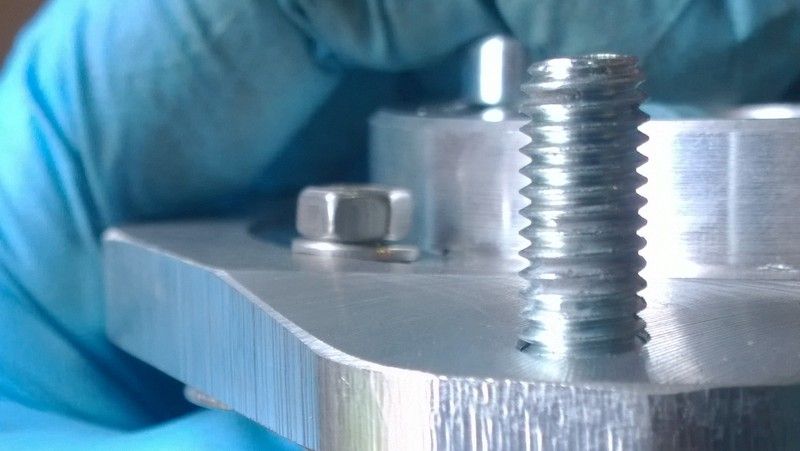

So, a few things we felt could be improve on the mount! we first of all noticed if the mount is fitted as it came to us, the complete weight of the car, which is held in the middle of the mount of course is actually held with 4 small m5 bolts, which are only 10mm long, and are only held by thread, no securing nut or anything. Which decided this, although it obviously does work, is a bit more of a risk than needed! As you can see in this picture, the head of the bolts barely make contact with the mount aswell

There are two fixes for this me and nige worked out.

Fix 1

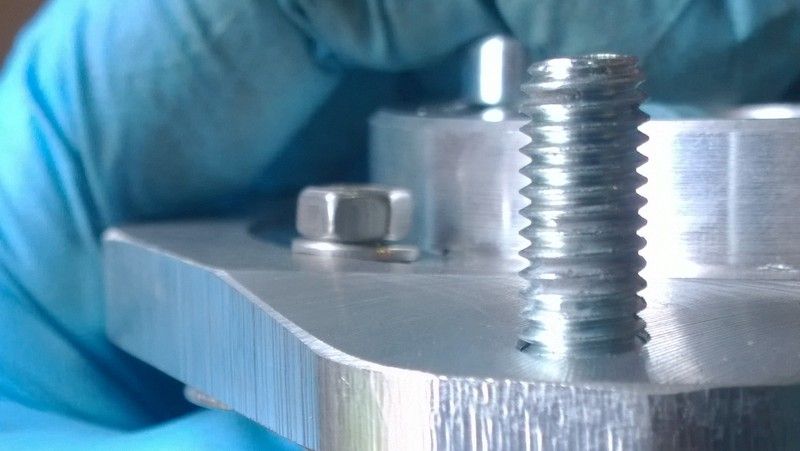

Cue the big washers and long bolts

so the longer bolts allow big penny washers on the bottom, big contact area underneath, spreading the load right across the ally mount, and the nuts on the top clamp the bolts in basically, as a back up for the fact the bolt holes are threaded anyway. A worthwhile upgrade imo thou.

washer were sitting on the wonk a tad so needed a flat edge, the nuts on the top are not tall nuts to allow clearance, this allows them to fit perfectly in the flare of the body of the car!

these could do with being Dome Allen Key Bolts as they run effin close to the top cup, i can get a rag between the cup and bolts head so they do clear, but i have since bought new allen bolts to replace them with

bolts need to be m5/0.8 and 16mm in length with nuts, penny washers and normal washers

So now we have had a chance to have a play with the mounts and fit them and came across a few things that need adjustment for a better fit, and general things to improve them!

obviously we would like to point out, once u receive your mounts, u can actually just chuck them on, they do fit and are usable, we just want to point out our thoughts, and of course.

We as a club are not responsible for the fitment, mods, or life of the mounts. this is just us covering our ass basically, After all, you all knew what u were ordering before you paid

its all up to you what you do, to receive your mounts, simply contact kev and he will post them to you!

its all up to you what you do, to receive your mounts, simply contact kev and he will post them to you! Right so lets begin!

Chamfer

so as a few of realised straight from the offset, the mounts being flat makes them different to the standard mount, standard mount is curved to allow for the shape of the body, where as these are flat.

The negative side of this is with the mount being flat is that only the outside edge of the mount will make contact with the body, this means more pressure on the edges due to uneven weight spread, and more likely to have flex in the mount, reducing the life.

As a result, we recommend gettin the mounts machined down or using a file to make a shape which matches the body of the vehicle.

The mount is made from 10mm aluminum, and this should be come 7mm at the outer edge, to give a chamfer identical to that of the body of the car.

Mount Improvements

So, a few things we felt could be improve on the mount! we first of all noticed if the mount is fitted as it came to us, the complete weight of the car, which is held in the middle of the mount of course is actually held with 4 small m5 bolts, which are only 10mm long, and are only held by thread, no securing nut or anything. Which decided this, although it obviously does work, is a bit more of a risk than needed! As you can see in this picture, the head of the bolts barely make contact with the mount aswell

There are two fixes for this me and nige worked out.

Fix 1

Cue the big washers and long bolts

so the longer bolts allow big penny washers on the bottom, big contact area underneath, spreading the load right across the ally mount, and the nuts on the top clamp the bolts in basically, as a back up for the fact the bolt holes are threaded anyway. A worthwhile upgrade imo thou.

washer were sitting on the wonk a tad so needed a flat edge, the nuts on the top are not tall nuts to allow clearance, this allows them to fit perfectly in the flare of the body of the car!

these could do with being Dome Allen Key Bolts as they run effin close to the top cup, i can get a rag between the cup and bolts head so they do clear, but i have since bought new allen bolts to replace them with

bolts need to be m5/0.8 and 16mm in length with nuts, penny washers and normal washers

Last edited: