So the paper came off

So first thing to get on with, I fancied a change of pace. So i took the up, put it on high axle stand on top of wood, get it as high as I could then dropped the ramp down so I could lay under the car.

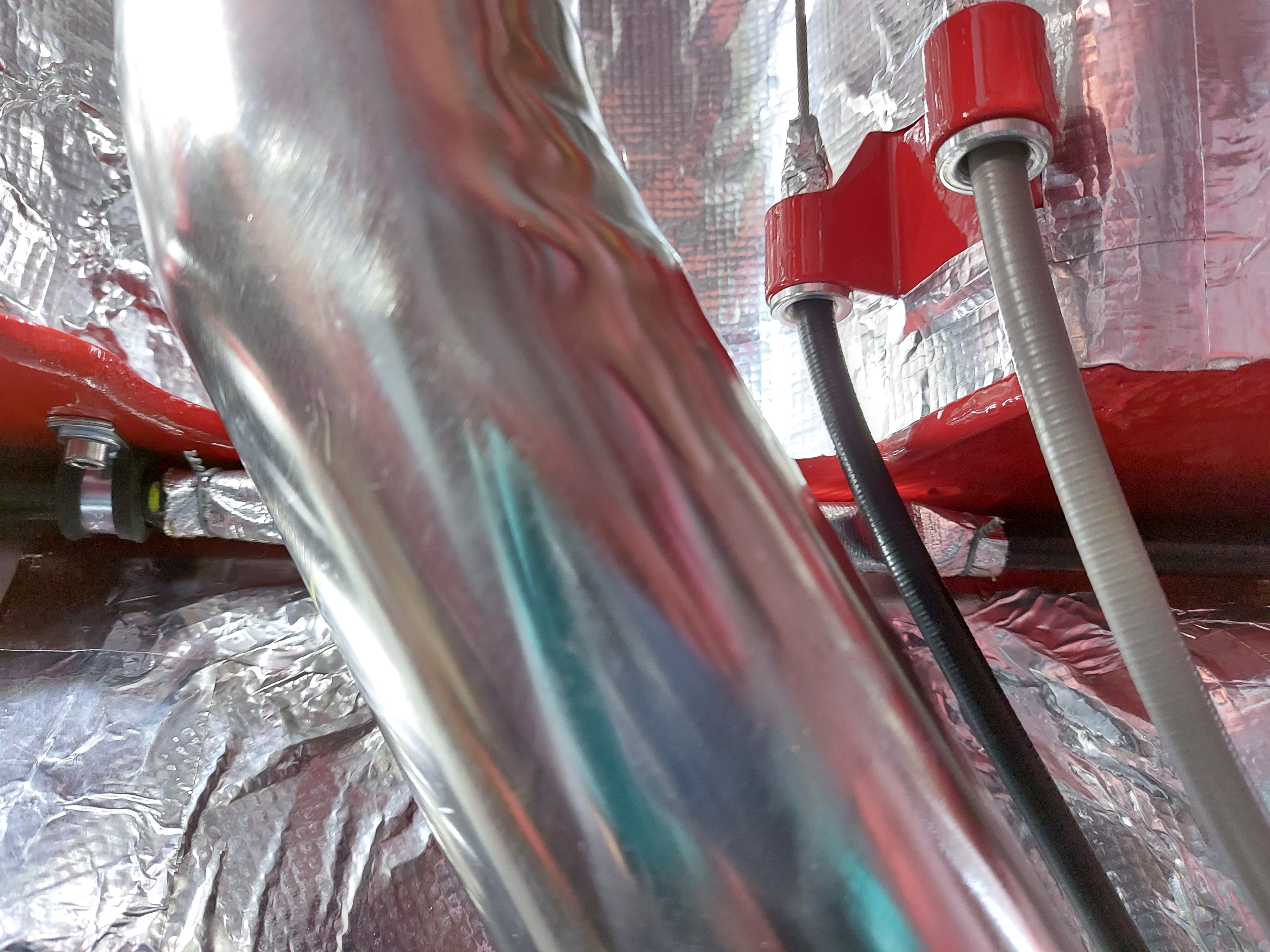

Ive had this stuff a fair while, so thought I should put it on.... heat shielding!

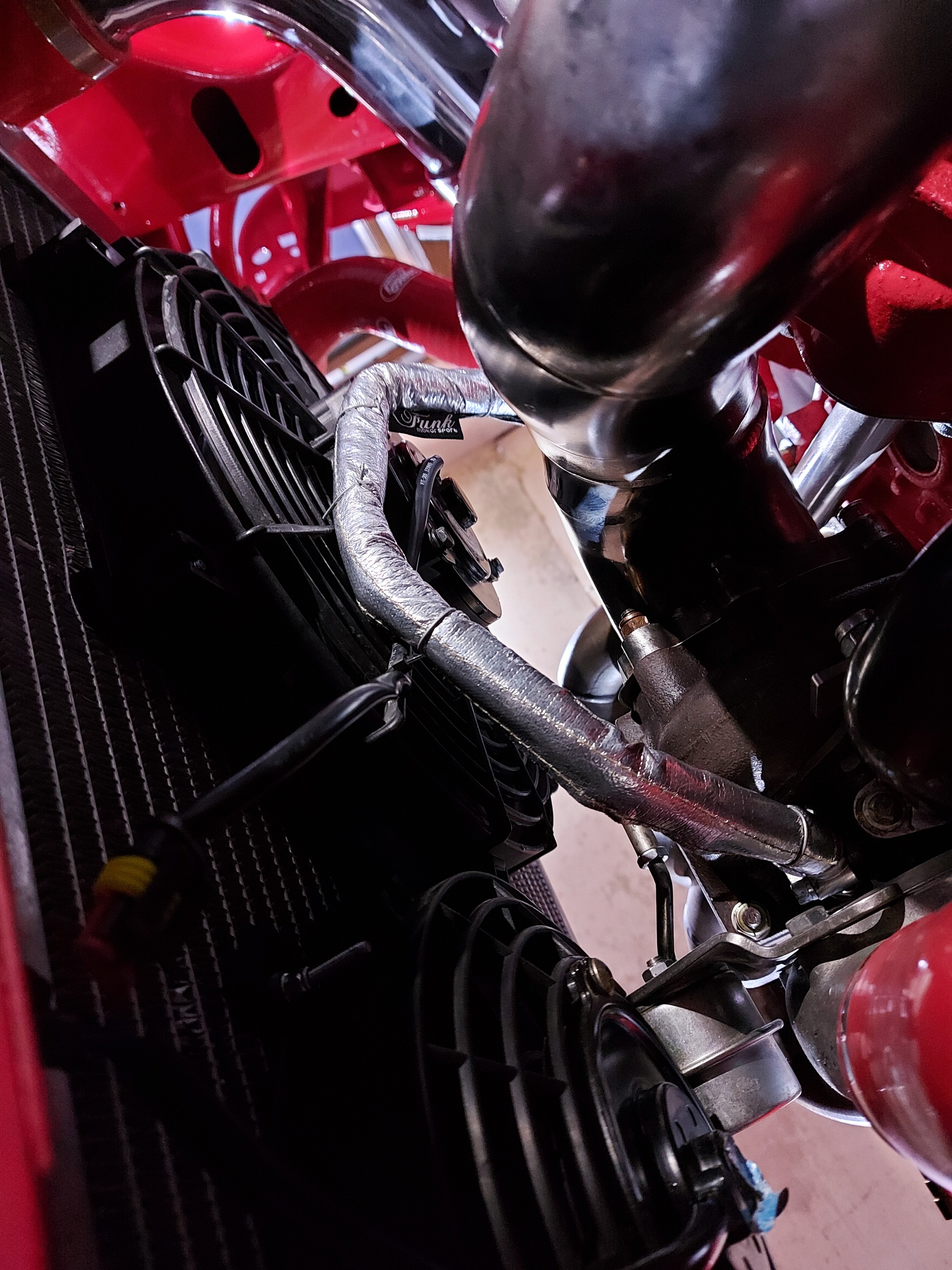

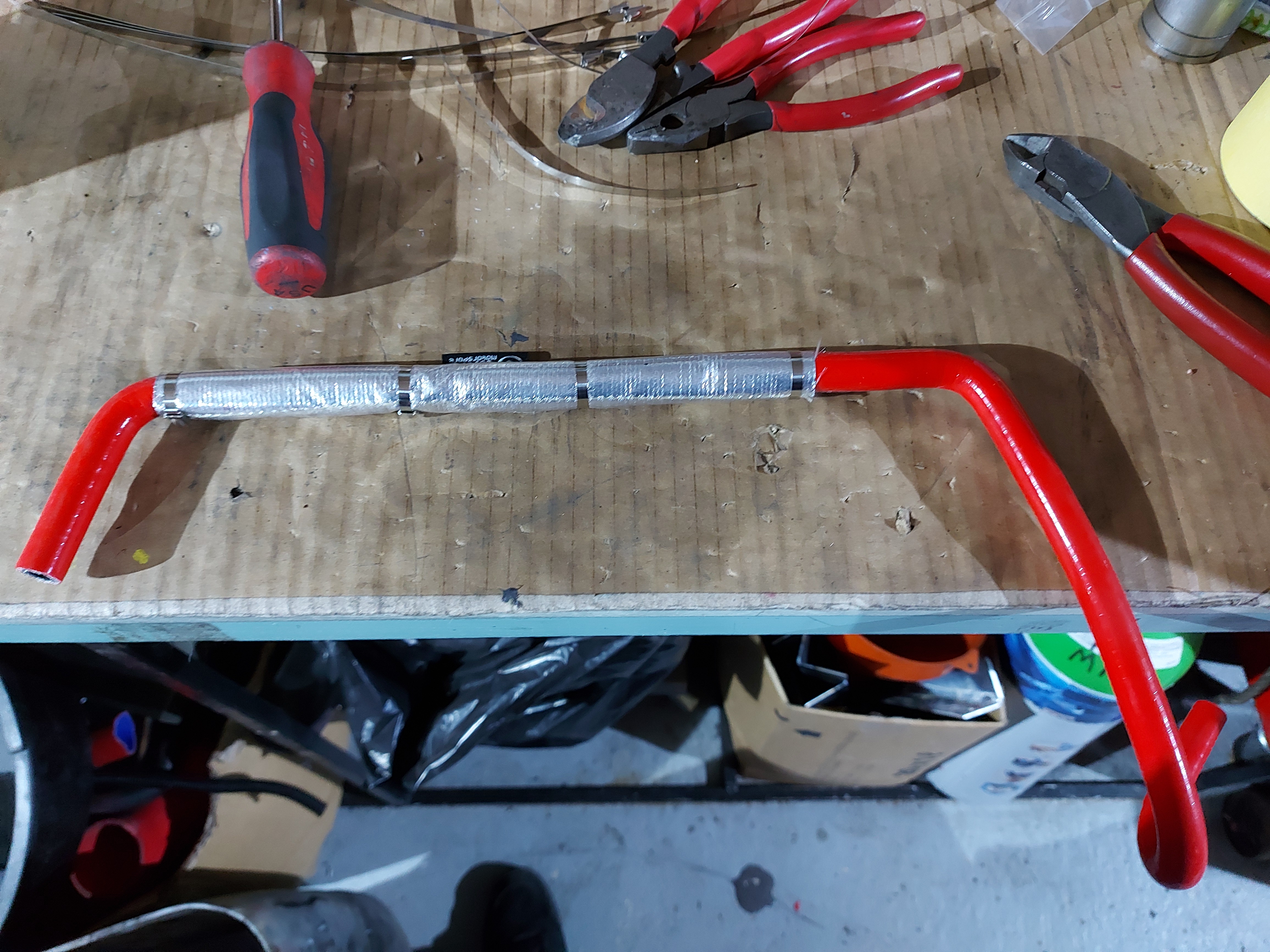

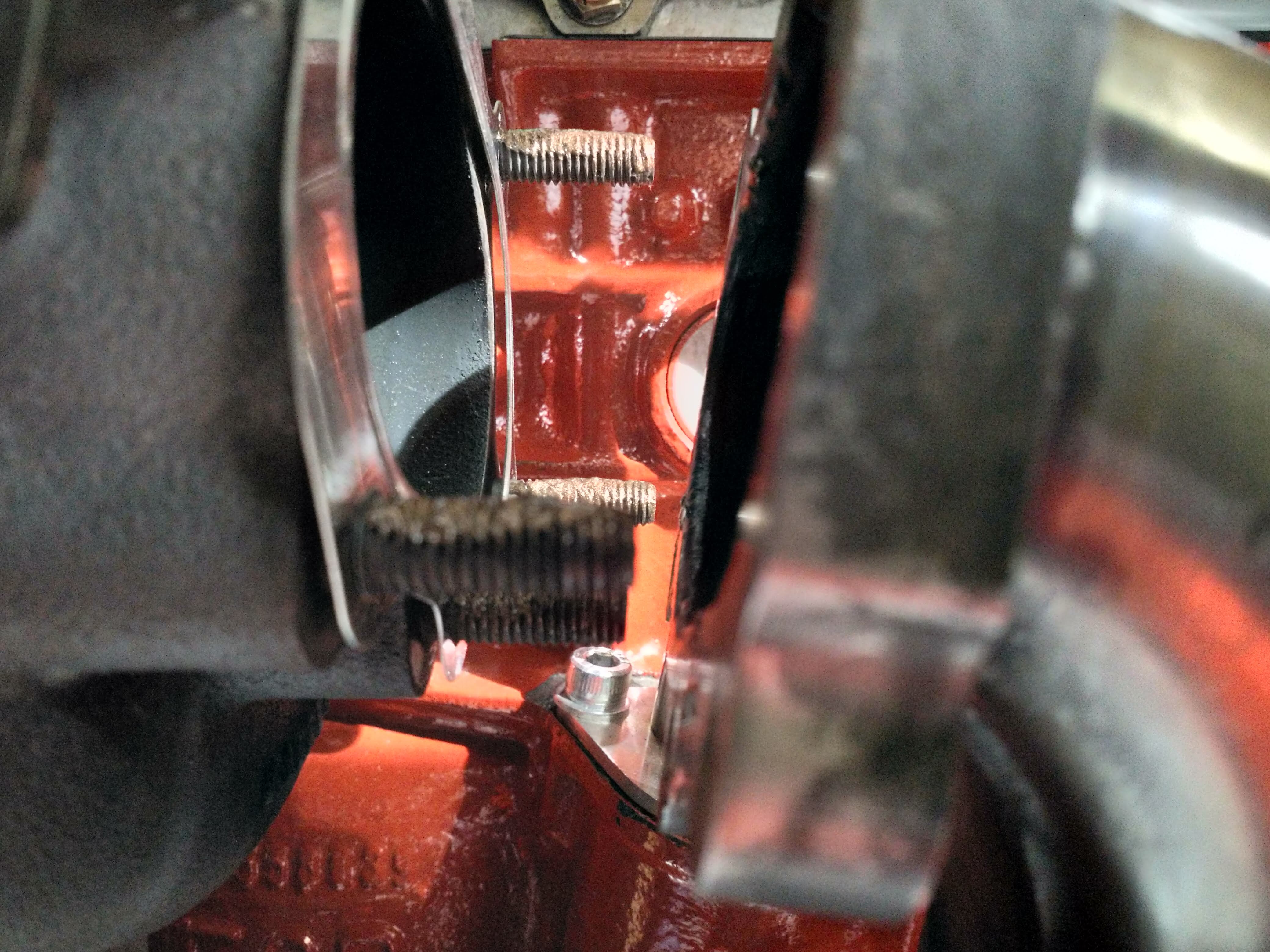

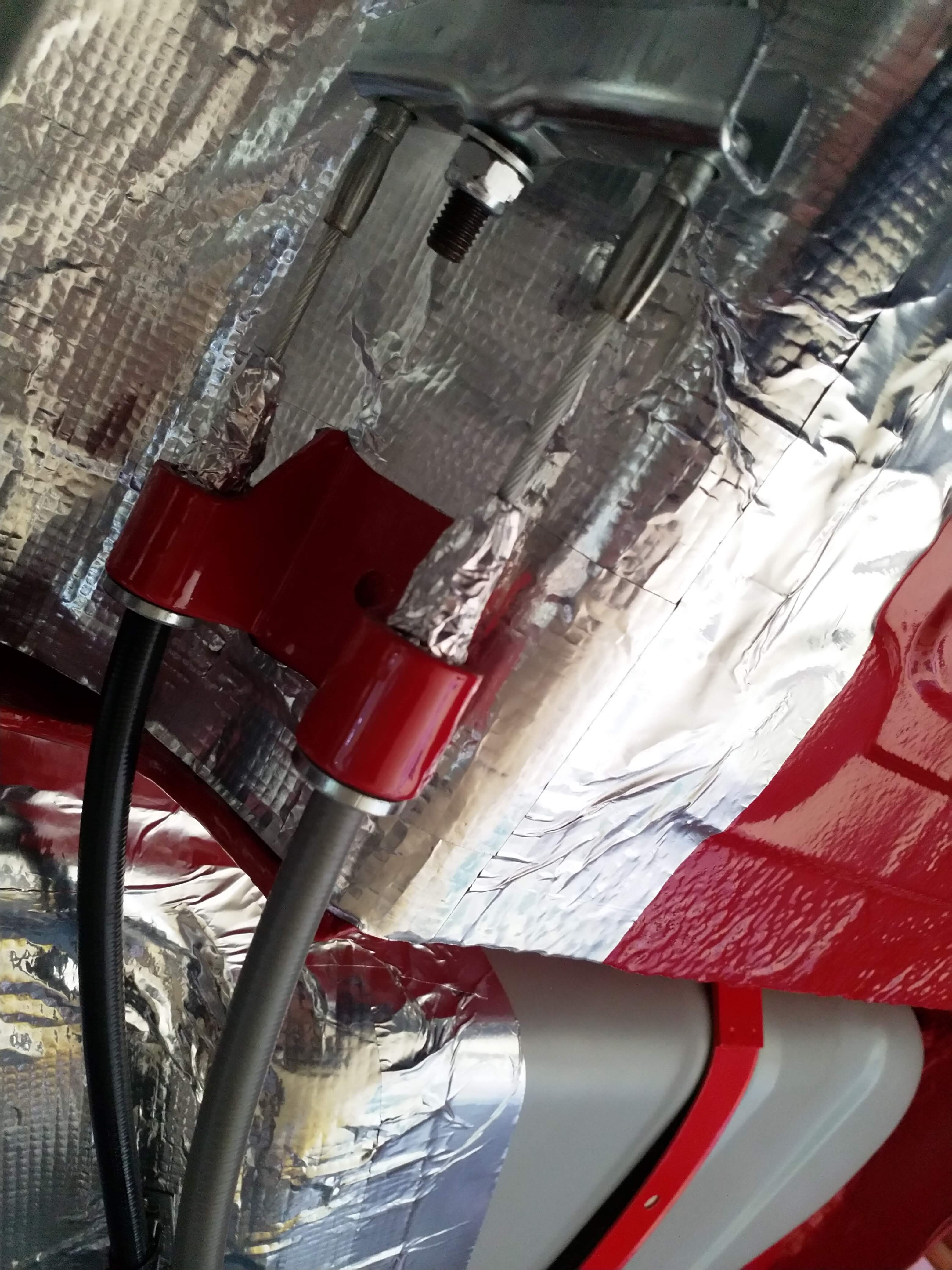

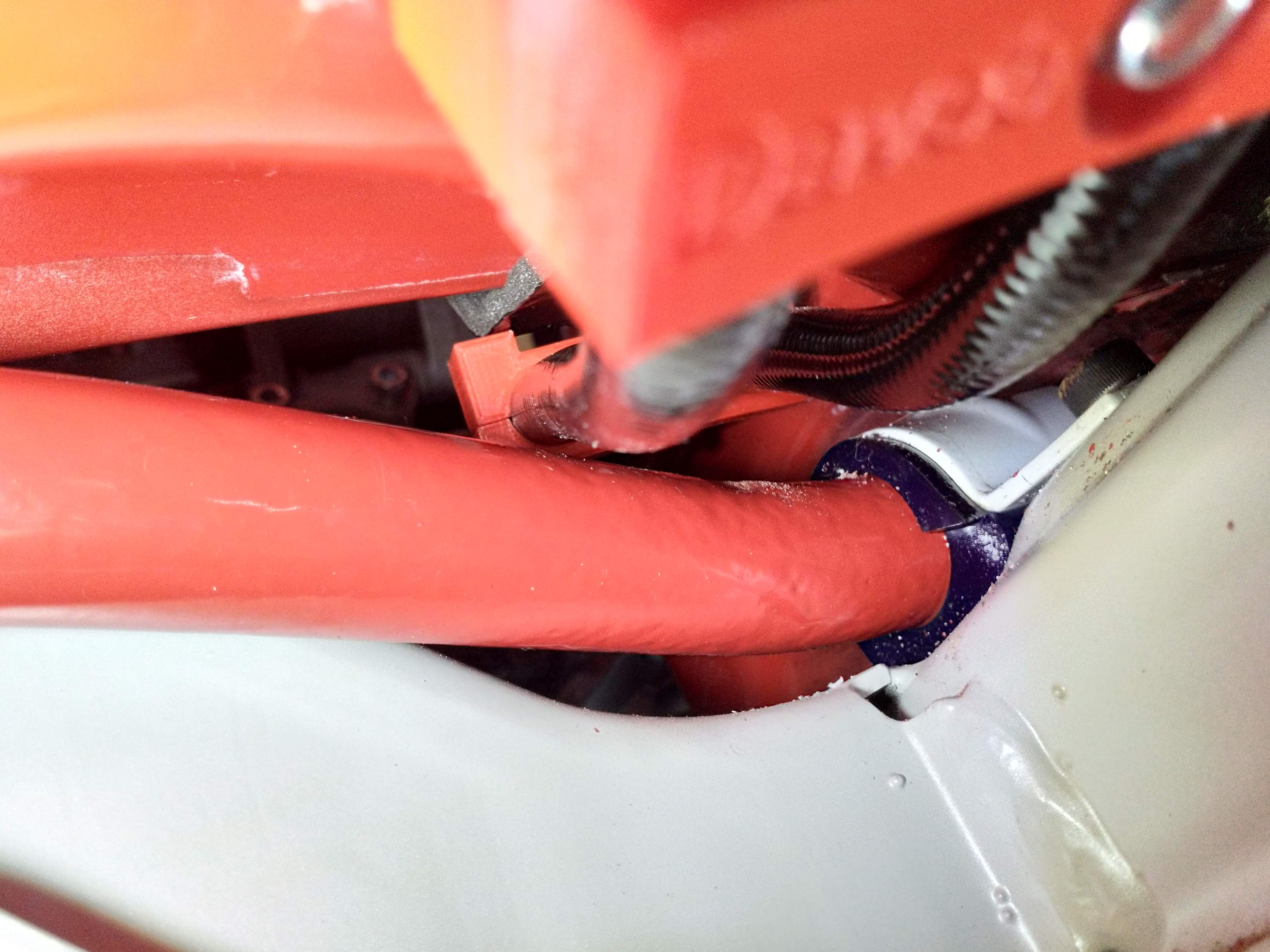

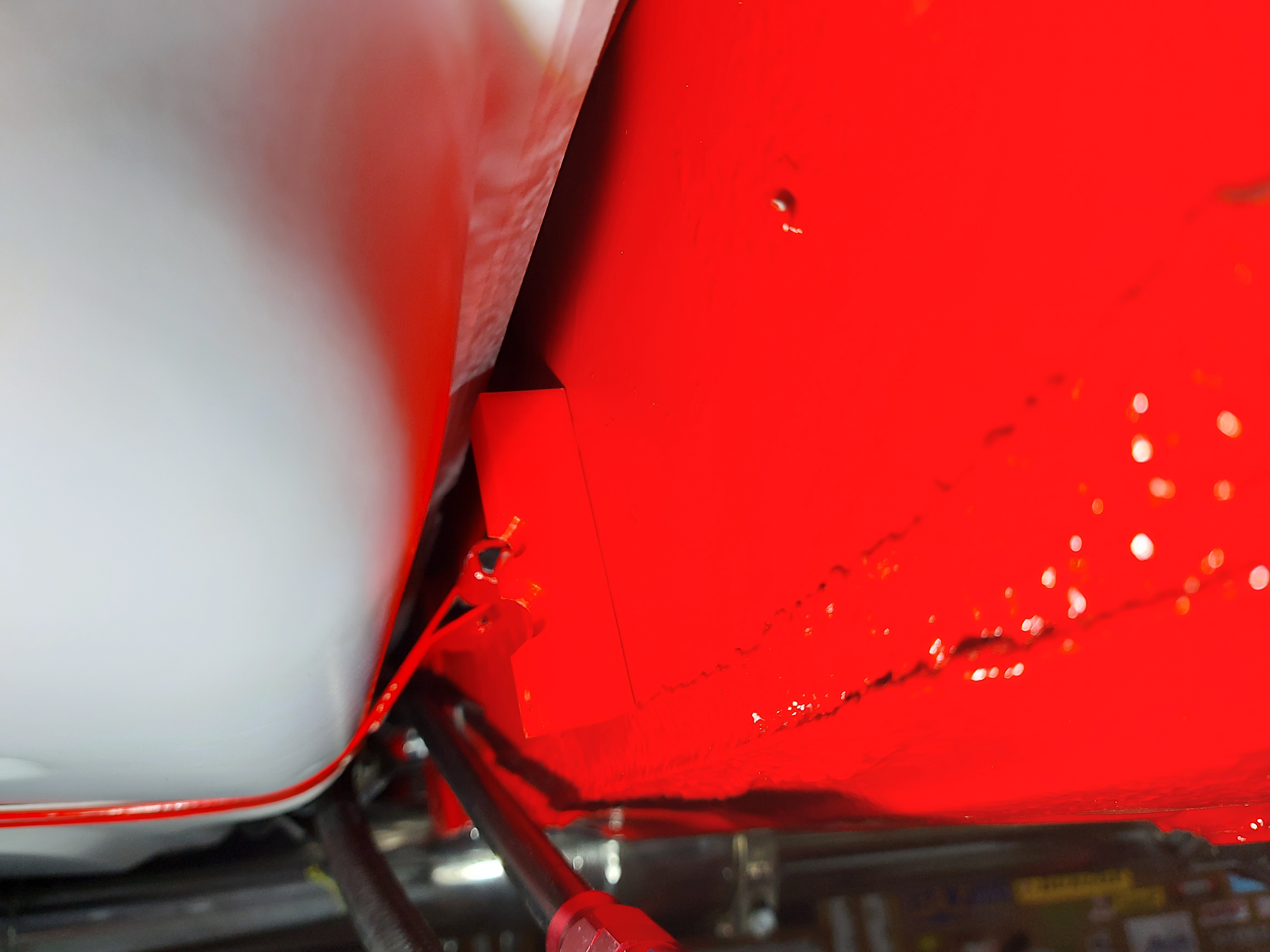

now my OE heatshields were in a bad way, but so bad that they were beyond a clean up and spray, they had rotted away, So i took the decision early on to use zircoflex heat shielding, self adhesive and flexiable. This stuff is heat proof to 550c..... that should do haha Its the ideal solution as making replacements would be impossible.

So today it was time to attack it. I ordered 2 big sheets and this turned up folded up in a bag... kinda annoying.... but then it became apprent very quickly that this stuff is impossible to put on without there being massive creases all over it lol.

Because of this I made my peace with it quickly and cracked on. Its definatly function over form, but once it was done, I really liked the look of it anyways!

So I got the first sheet on there

There in some crazy shaped in the exhaust tunnel it turns out lol

But then I finished the edges with aluminium tape. This made the whole thing alot nicer finish to look at, but also will stop water getting under the tape and lifting it..... should I ever get caught in the rain...... which i hope not

I also did the fuel tank which doesn't actualy have a heatshield from factory but seemed like a good idea

and all done

all that is left is to do is where the back box goes....

I didn't order this straight away incase i wasn't convinced, but the stuff seems really good and it's mega mega sticky! So that should turn up soon!

So first thing to get on with, I fancied a change of pace. So i took the up, put it on high axle stand on top of wood, get it as high as I could then dropped the ramp down so I could lay under the car.

Ive had this stuff a fair while, so thought I should put it on.... heat shielding!

now my OE heatshields were in a bad way, but so bad that they were beyond a clean up and spray, they had rotted away, So i took the decision early on to use zircoflex heat shielding, self adhesive and flexiable. This stuff is heat proof to 550c..... that should do haha Its the ideal solution as making replacements would be impossible.

So today it was time to attack it. I ordered 2 big sheets and this turned up folded up in a bag... kinda annoying.... but then it became apprent very quickly that this stuff is impossible to put on without there being massive creases all over it lol.

Because of this I made my peace with it quickly and cracked on. Its definatly function over form, but once it was done, I really liked the look of it anyways!

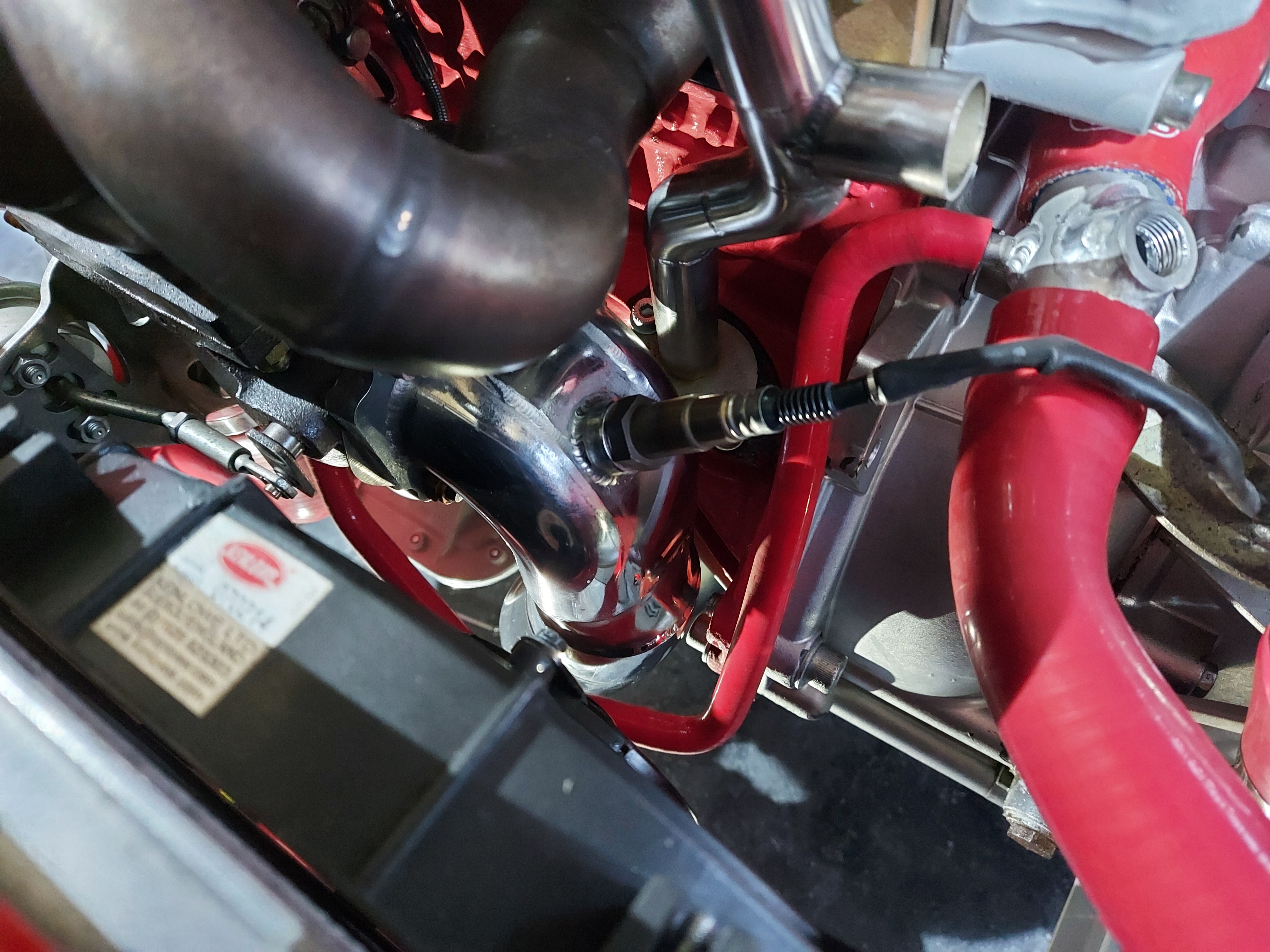

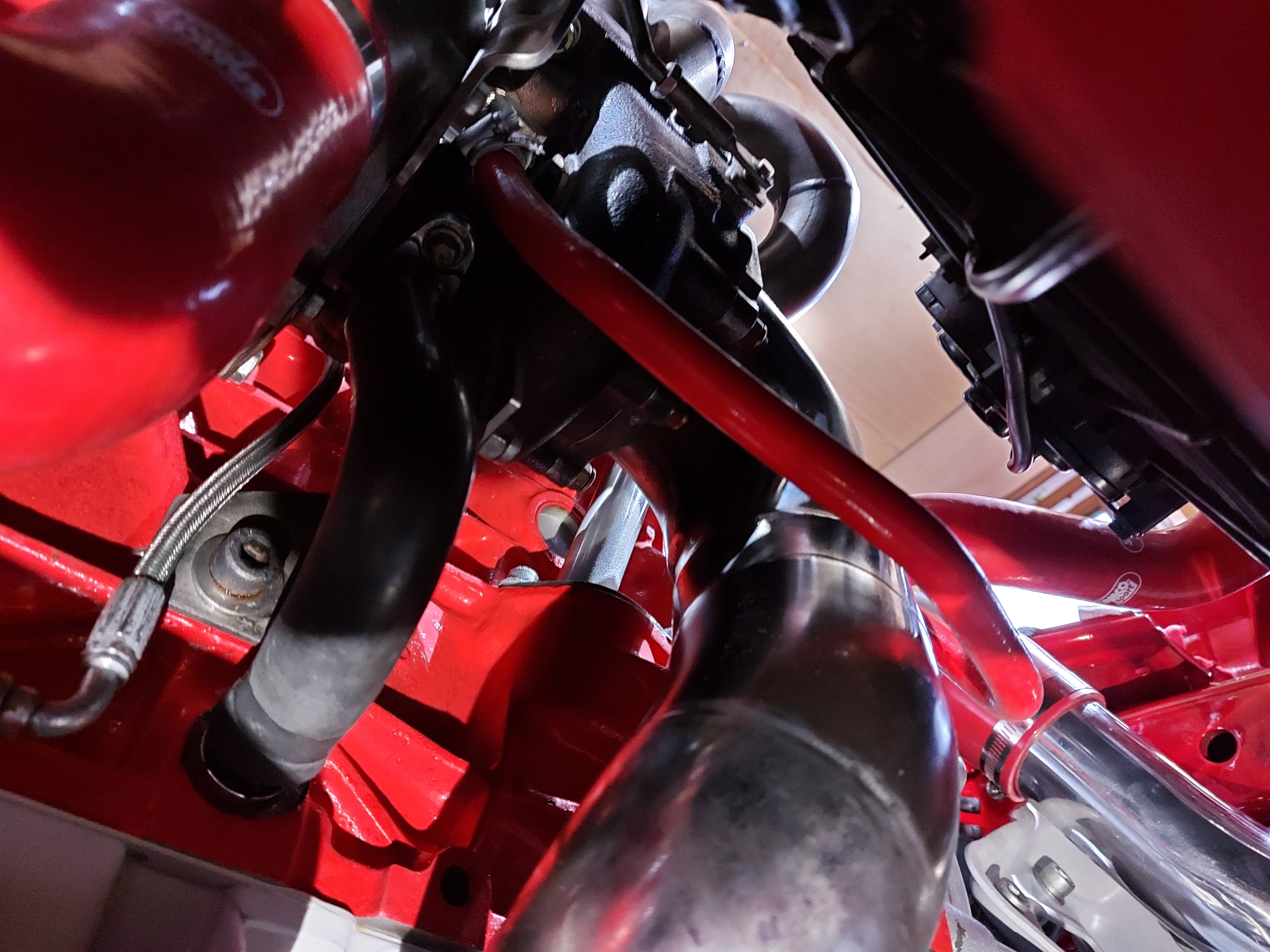

So I got the first sheet on there

There in some crazy shaped in the exhaust tunnel it turns out lol

But then I finished the edges with aluminium tape. This made the whole thing alot nicer finish to look at, but also will stop water getting under the tape and lifting it..... should I ever get caught in the rain...... which i hope not

I also did the fuel tank which doesn't actualy have a heatshield from factory but seemed like a good idea

and all done

all that is left is to do is where the back box goes....

I didn't order this straight away incase i wasn't convinced, but the stuff seems really good and it's mega mega sticky! So that should turn up soon!

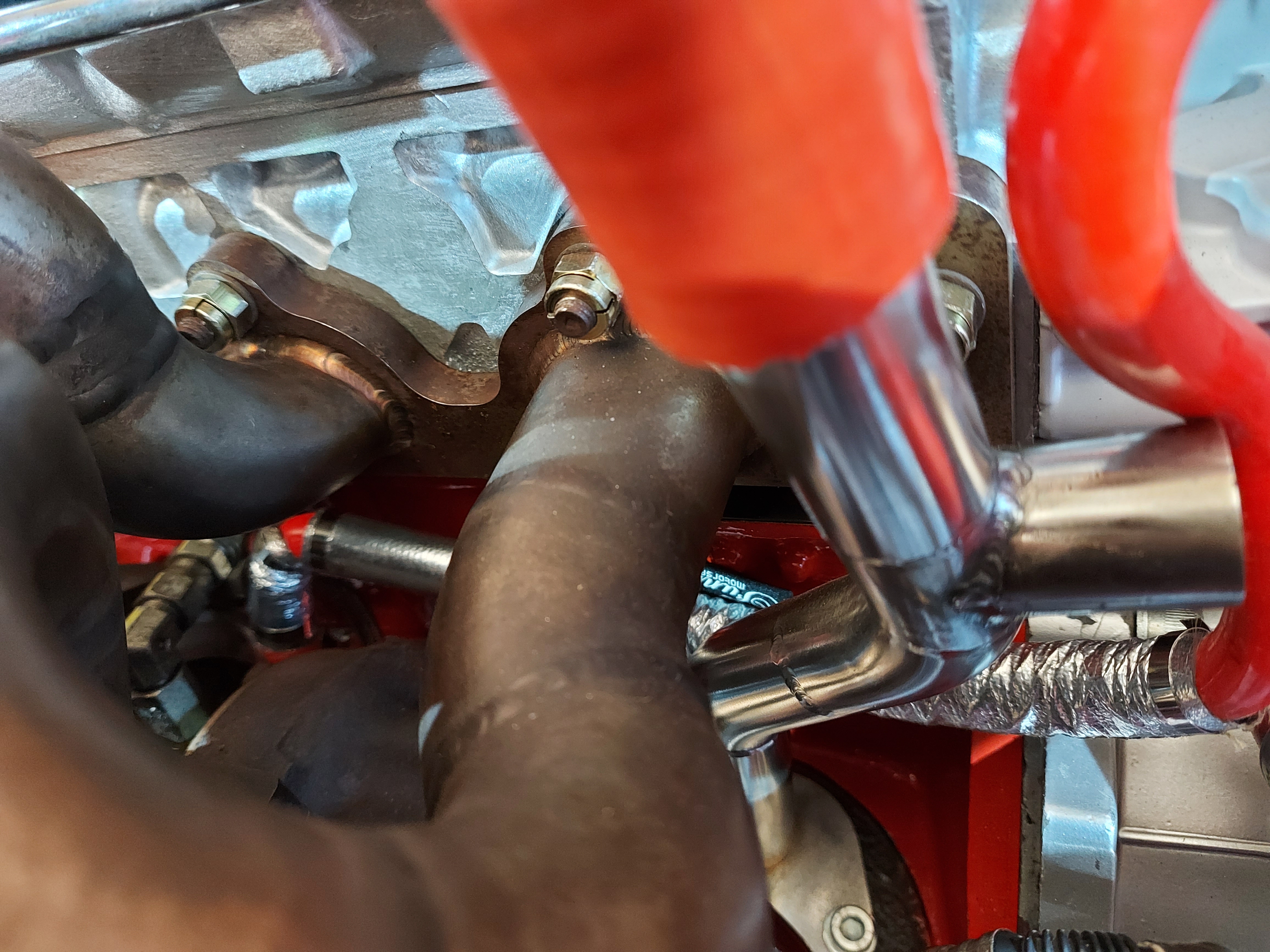

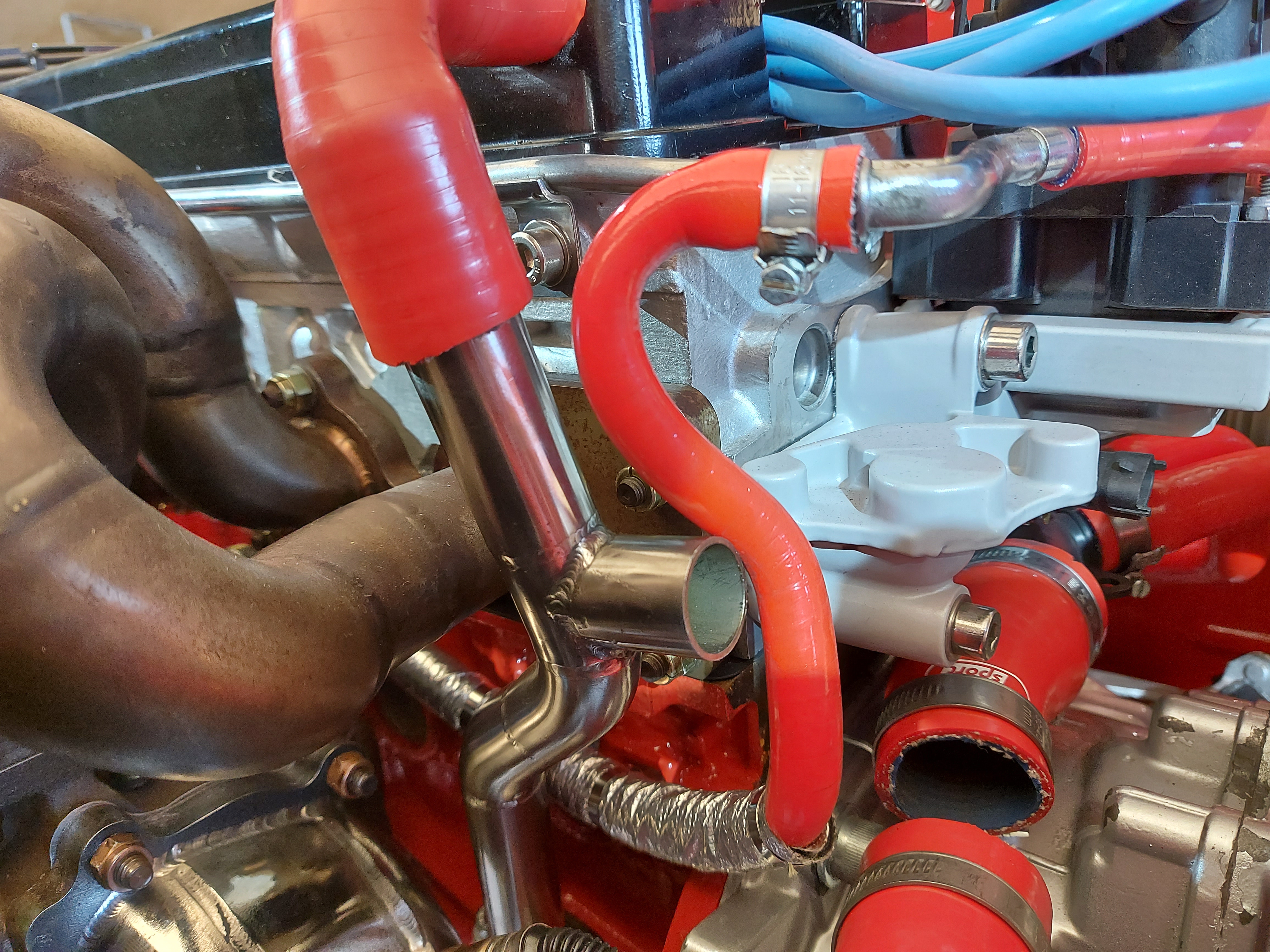

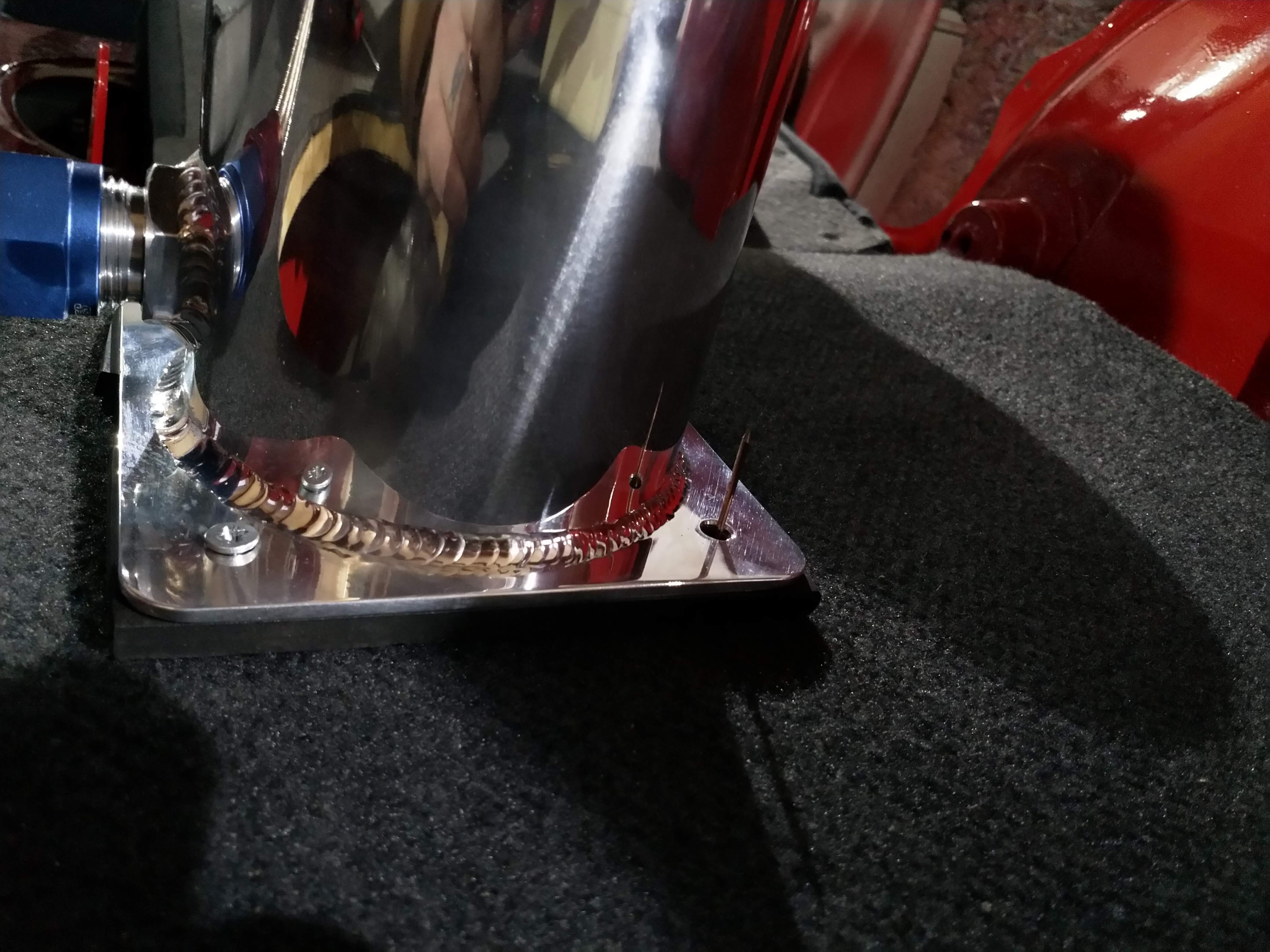

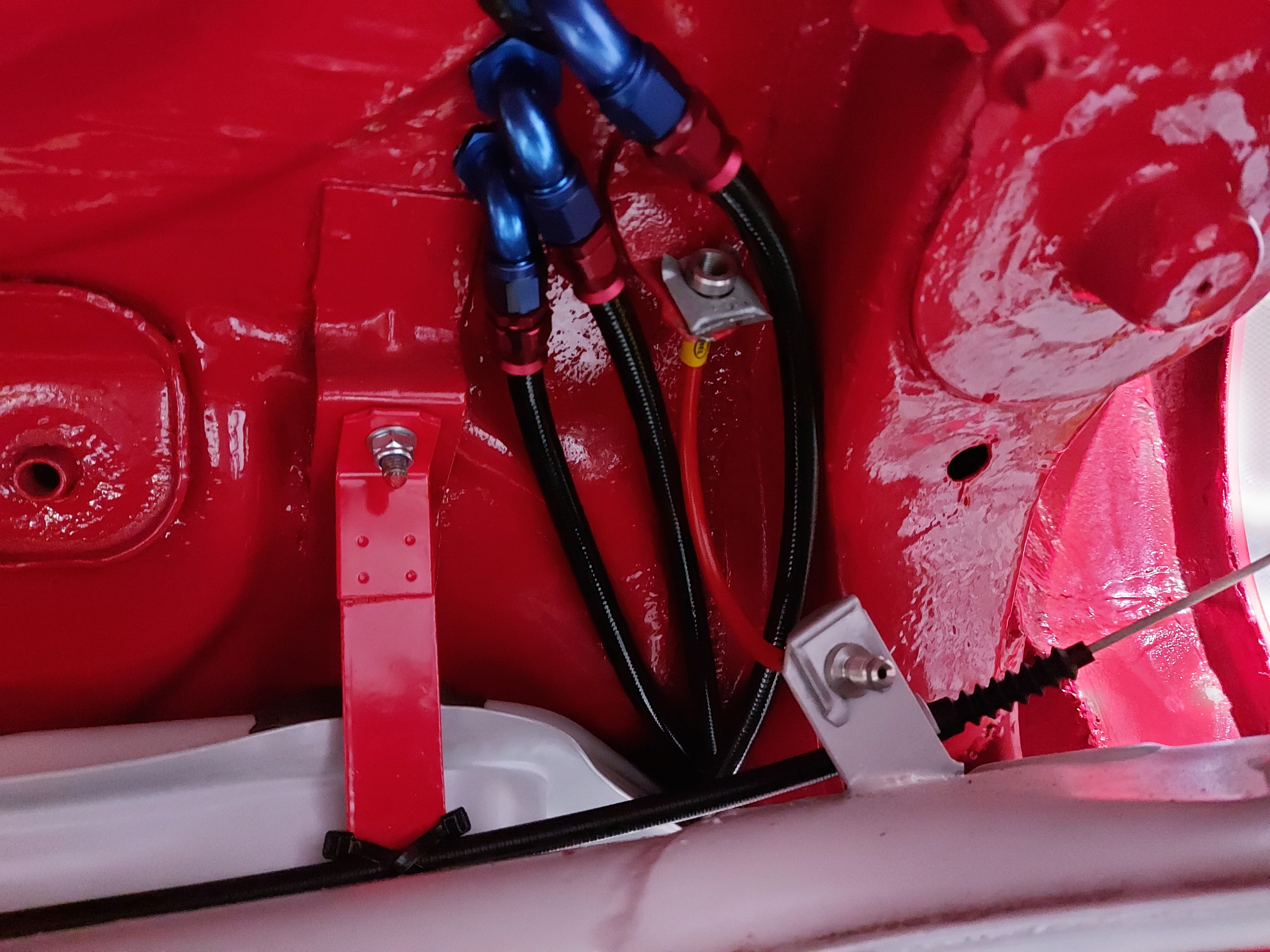

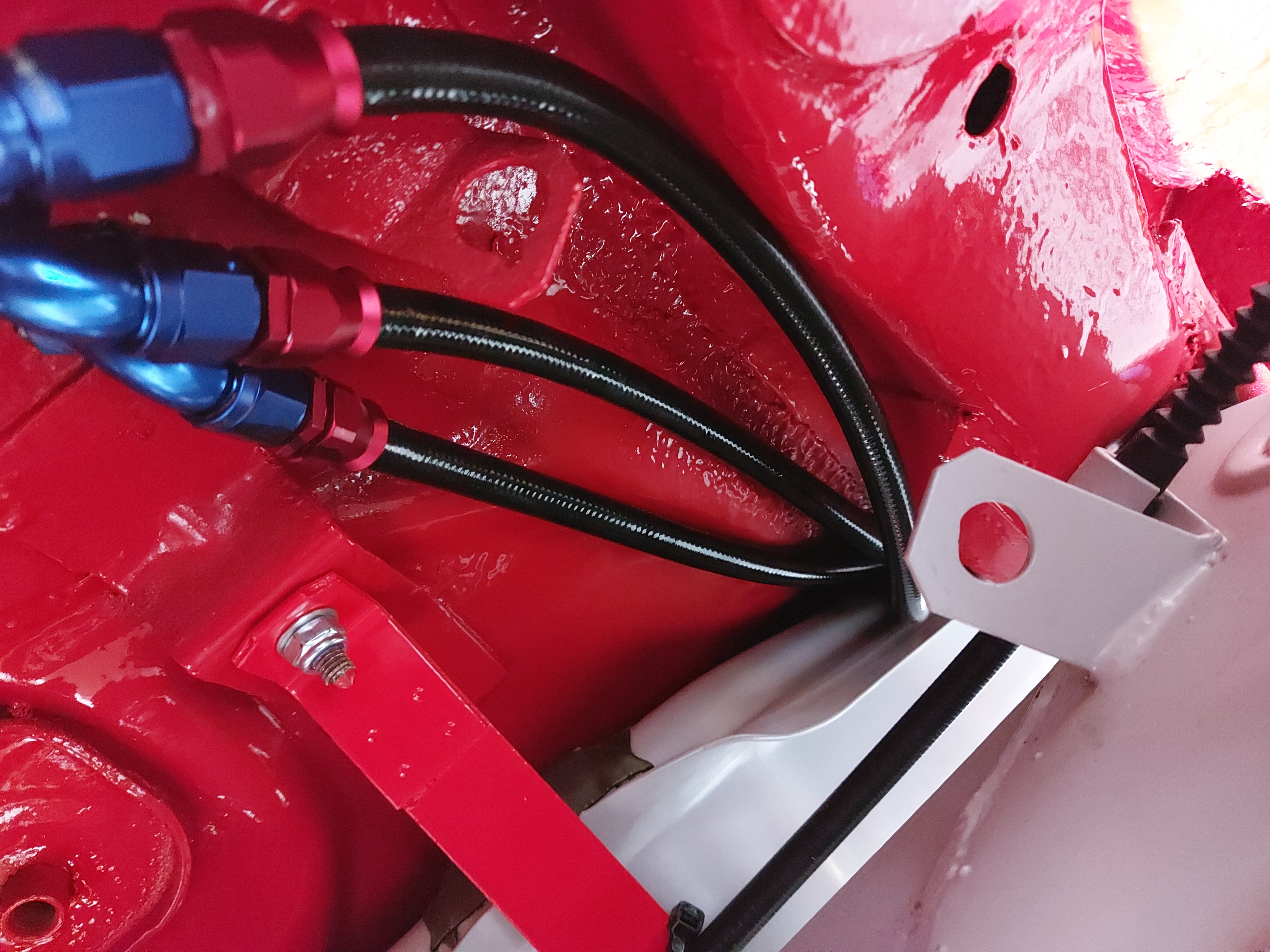

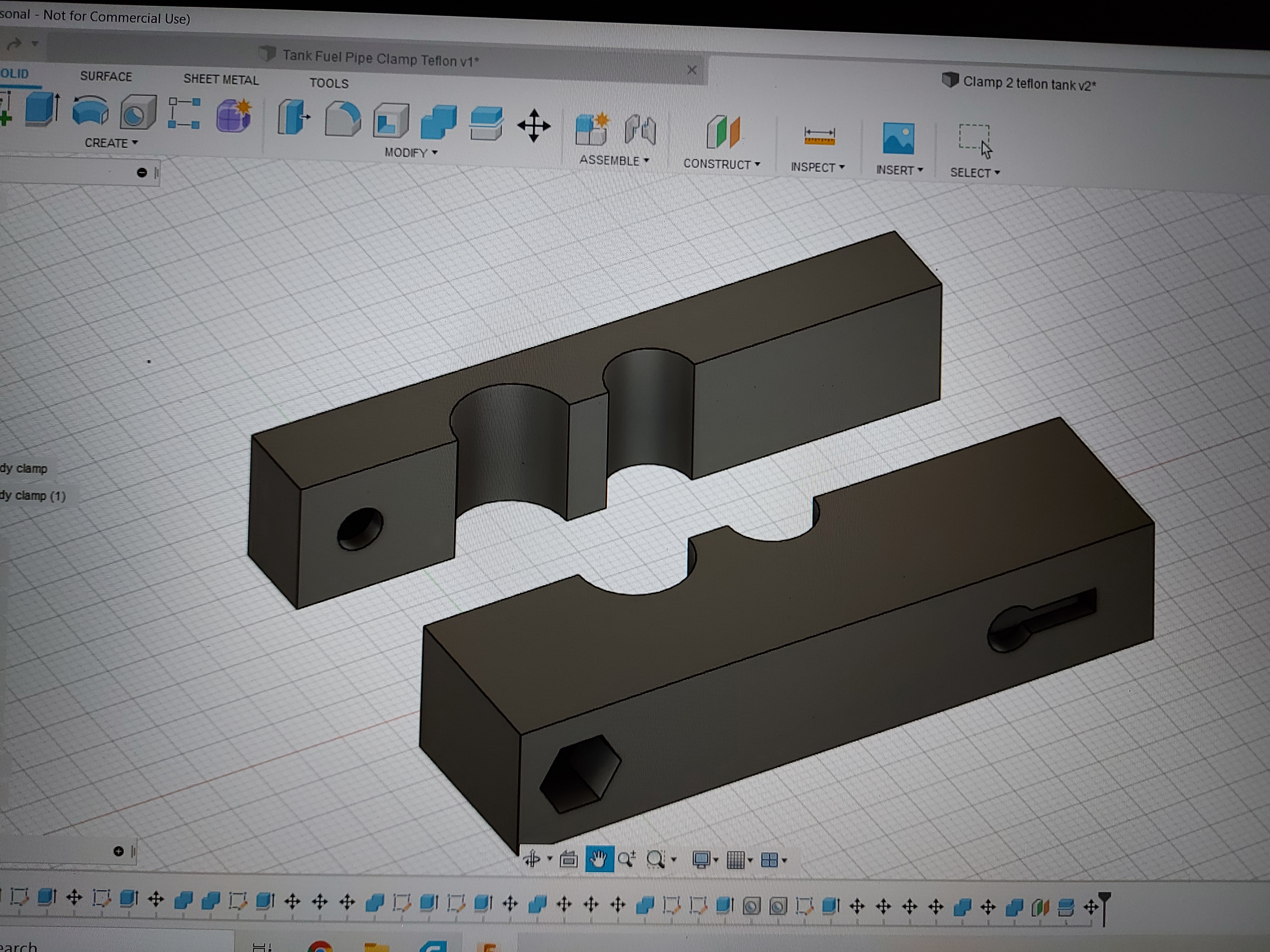

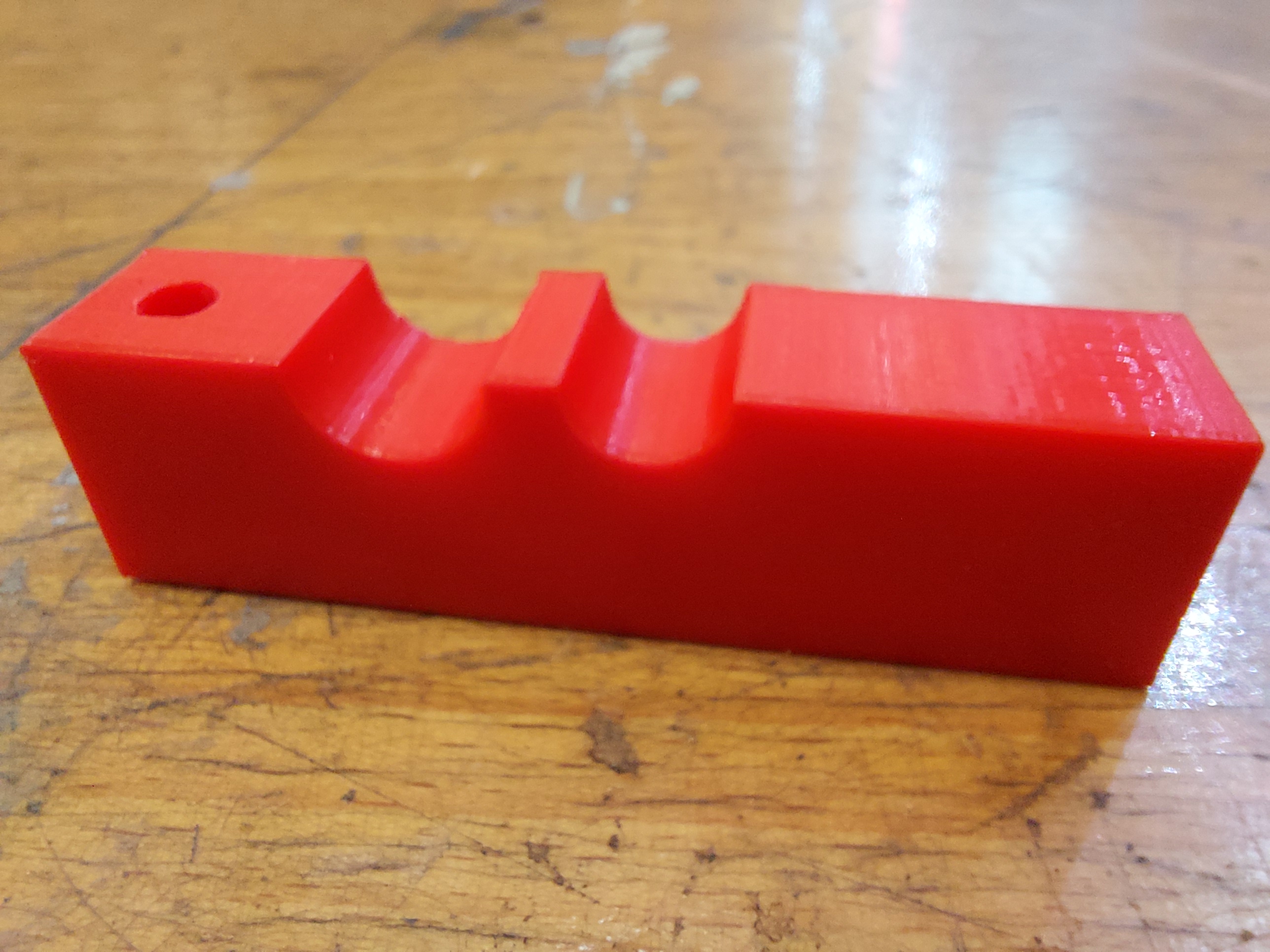

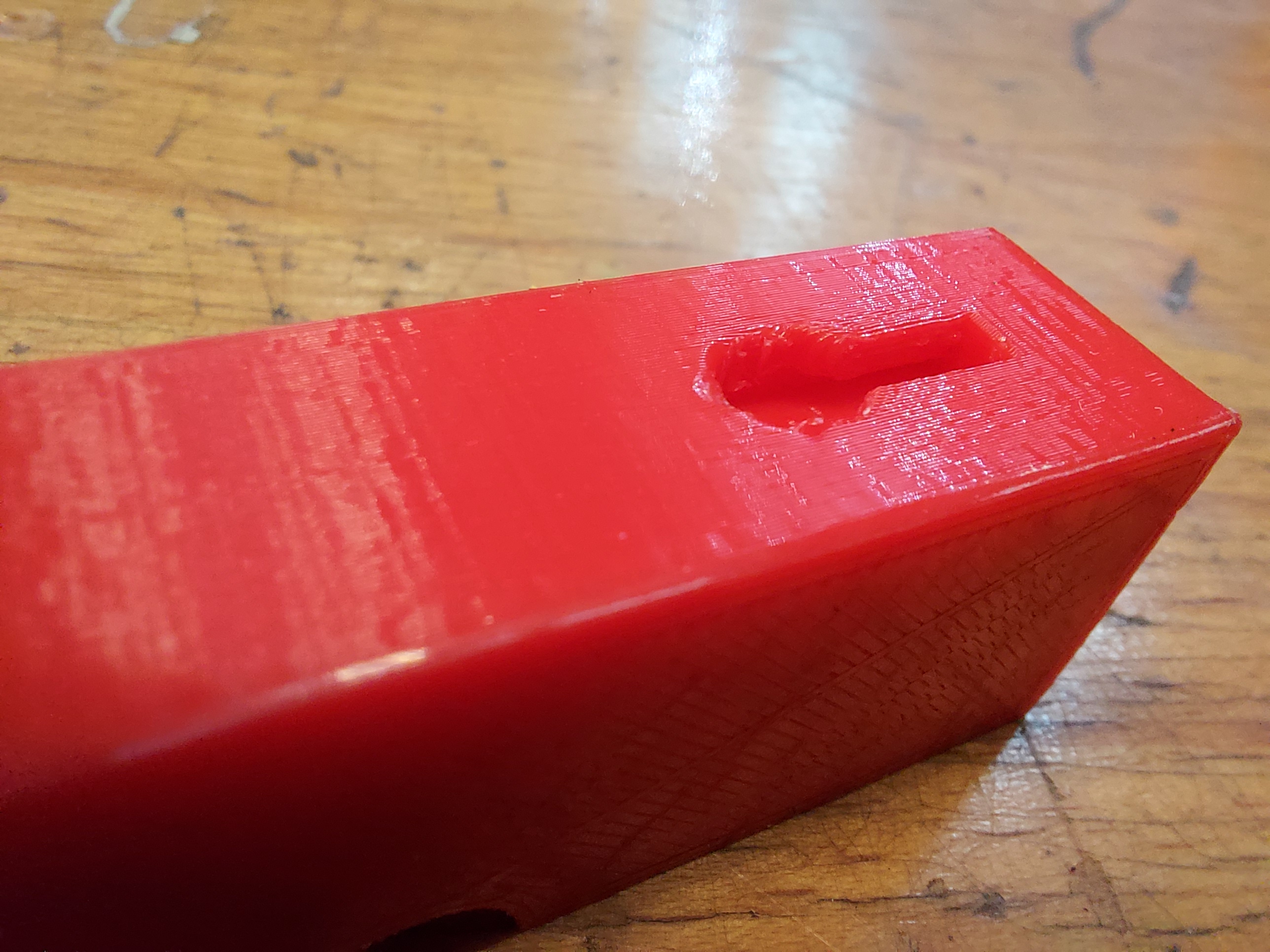

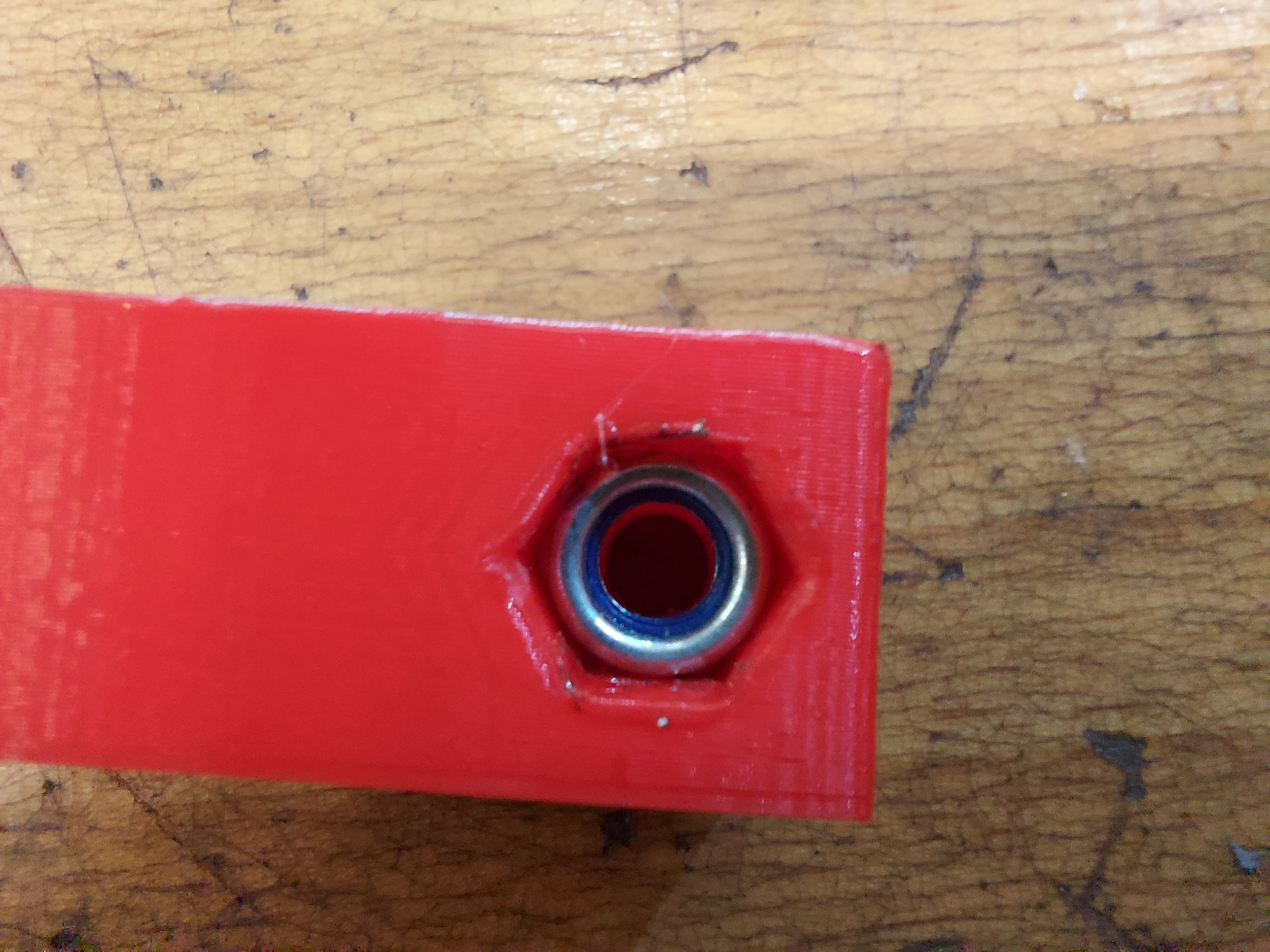

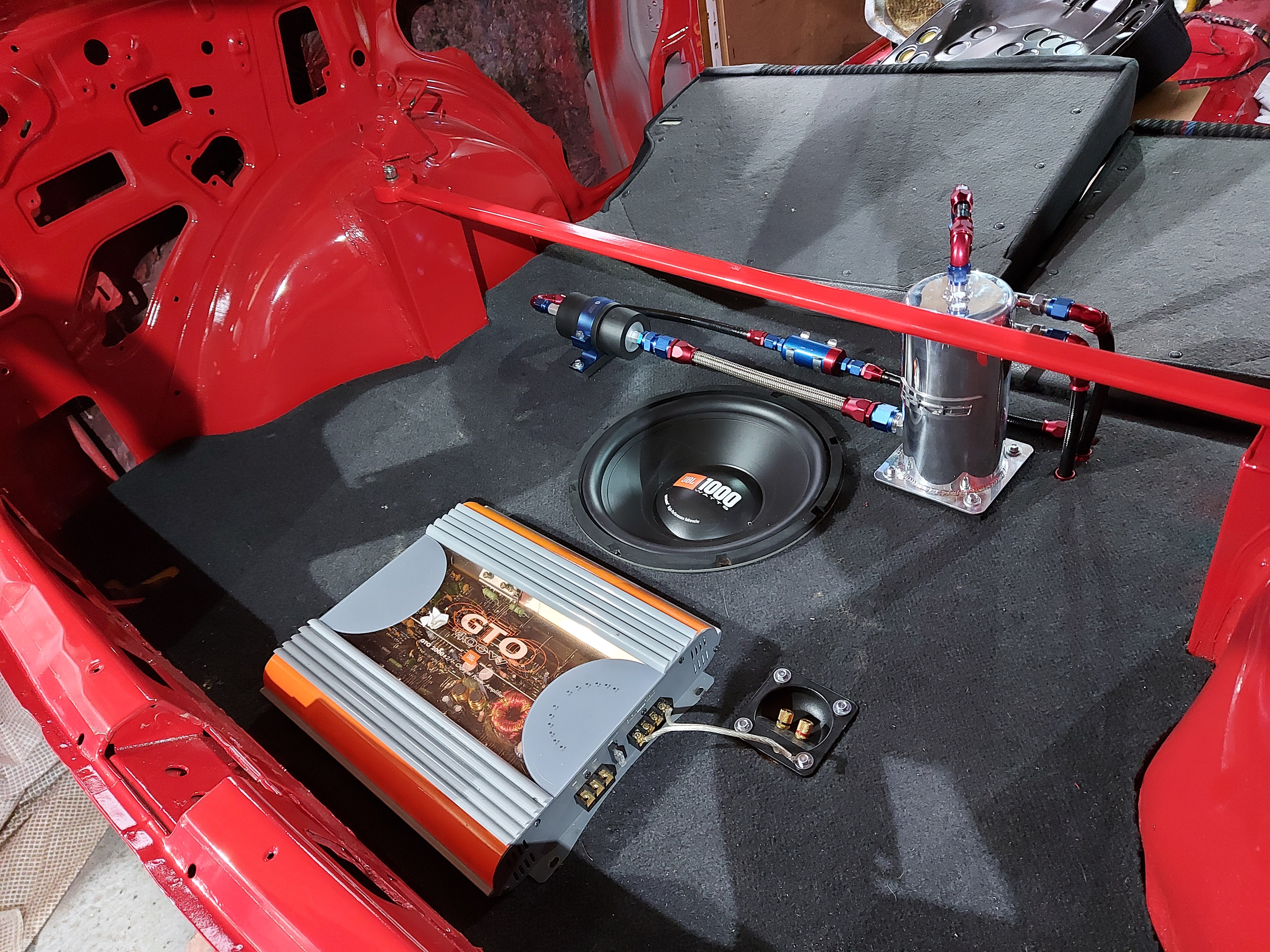

...... this might be a surprise to you aswell haha. It was pretty easy after that. The fittings from torques on ebay are really well made

...... this might be a surprise to you aswell haha. It was pretty easy after that. The fittings from torques on ebay are really well made